Overview

The aim of this Innovate UK-funded project was to develop the technology to map and interpret the surface damage observed in failing rail axle bearings, with a view to improving rail safety and enabling train companies to optimise their rolling stock maintenance.

We worked with our partners, Scantron Industrial Products Ltd and Perpetuum Ltd, to determine the relationship between vibrations recorded during operation and damage found in rail axle bearings.

This brought together two elements:

- The vibrations were measured using a condition monitoring system produced by Perpetuum Ltd and fitted on the bearing test rig.

- The rolling contact fatigue (RCF) damage was measured using the BEARING-EYE, a state-of-the-art instrument developed by Scantron Industrial Products Ltd during the project.

By running bearings on the bearing test rig and removing them at specific intervals to analyse the surface damage, we could also gain insights into the propagation of RCF.

The BEARING-EYE

Scantron’s BEARING-EYE is a custom-developed scanning system, combining high-integrity precision mechanics, high-speed electronics and the latest sensor technologies.

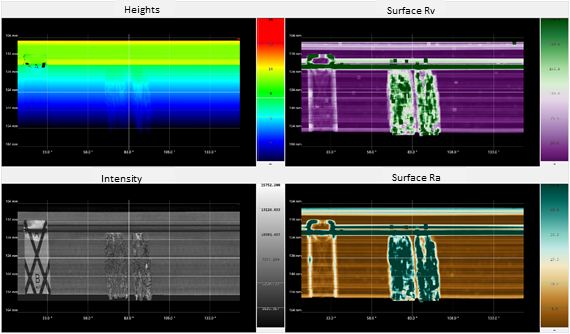

Two non-contact sensors are able to measure the surface topology of the entire bearing surface. A chromatic aberration sensor, that can measure to ~10 nm vertical resolution, is complemented by a non-contact line laser sensor capable of capturing millions of data points per second. The system is also equipped with an optical camera for white-light imaging of the bearing.

Learn more by downloading the BEARING-EYE whitepaper that was published in the Rail Technology Magazine in March 2021.

Below you can watch the BEARING-EYE in operation and see the data produced by one bearing scan.

An AI software platform, able to process and interpret the data recorded by the BEARING-EYE, is currently being developed in close partnership with nC2. At the push of a button, this innovative and smart software will be capable of evaluating and defining the severity of the damage found in bearings.

Watch the BEARING EYE scanning the bearing internal surface.

Surface map of one race of a bearing measured by the BEARING EYE.

The bearing test rig

The bearing test rig is a new state-of-the-art instrument owned by Perpetuum Ltd and housed at the University of Southampton. It is able to run rail axle bearings at speeds and loads similar to those of the rail environment. While running, vibration data are collected using sensors provided by Perpetuum Ltd, who are experts in condition monitoring. Using this rig we can create damage, which can be measured with the BEARING-EYE, to better understand the propagation of rolling contact fatigue in rail axle bearings.

Watch the bearing test rig in action.

Watch Dr Ilaria Corni closing a rail axle bearing.

Watch the team inserting the bearing into the sleeve before testing.

Watch Dr Ilaria Corni and Dr Nicola Symonds changing a bearing before testing.