nC2 is delighted to be playing a part in the conservation of an iconic piece of the UK’s maritime heritage – Nelson’s flagship at the Battle of Trafalgar, HMS Victory.

The engineering consultancy is working with the National Museum of the Royal Navy (NMRN) to design and run a suite of tests to assess the performance of a range of paints, caulking and glues, and metal fastenings. The results will provide the evidence-based data NMRN needs to select the right products for a major programme to replace the ship’s outer planking, and to inform its maintenance plans into the future.

The challenge – making the ship watertight

Much of the planking was replaced during a restoration project in the 1980s and 90s, but unfortunately the types of wood chosen did not stand the test of time; the planking is now breaking down and letting rainwater into the ship.

Sam Hambrook (UoS) examining the paint under the ship

Diana Davis is Head of Conservation at NMRN. She explains: “Rainwater is probably our biggest enemy in terms of the ship’s preservation, so we’re undertaking a 10-year programme of work to replace the external planking and some of the internal planking, to make sure the critical envelope of the ship is weathertight.”

“This time we want to make sure we know as much as possible about the materials we are using” adds Diana. “It’s essential that we take an evidence-based approach to choosing the right products, and nC2 is helping us to do that.”

Being able to predict the products’ rate of decay is a key factor, as Diana explains: “Our aim is to bring the ship up to a condition that means no further major work will be needed in the next 50 years. Even if there’s no perfect product that will last that long, the data nC2 provides will enable us to plan our maintenance schedule to keep the ship watertight.”

Finding the right products to protect a unique vessel

Diana Davis of NMRN briefs the University experts

From the start, nC2 worked closely with NMRN to understand their requirements and tailor the tests to HMS Victory’s specific needs. Diana comments: “They understood the brief quickly and asked the questions we would expect, and the design they came up with for the analysis work was exactly what we wanted. They also worked with us to adjust and refine the tests.”

nC2‘s Director, Professor Nicola Symonds, says: “We designed the tests from the ground up, informed by research into the relevant standards and taking into account the ship’s specific environment. For example, it is situated in the open air in a dockyard site, so will be affected by rain, wind and salt, and much of the planking is painted black so will get hot in the sun on one side but not the other.”

Simulating the effects of time and weather

To identify the most suitable products for the ship, the nC2 team is undertaking a range of tests on specially prepared samples; the tests are repeated with different combinations of products, and on samples that have been treated to simulate the effects of wear, rain, sunlight and time.

Rachel Triggs and Dr Spencer Court testing the properties of treated oak samples

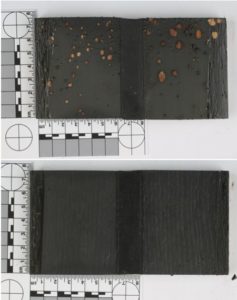

For example, the paint is tested for adherence to the wood, flexibility and water resistance, using freshly painted samples. The same tests are then undertaken on samples that have been ‘aged’ using UV and salt spray, and samples that have been cooled or heated to specific temperatures.

“Each test produces metrics that are used to provide comparisons and ultimately enable the different products to be ranked,” Nicola explains. “In themselves the tests are relatively simple, but when you take into account that we’re using hundreds of samples and multiple combinations, it’s a complex task.”

As well as hard scientific evidence, nC2 is bringing a practical perspective by feeding back on how user friendly the products are. Diana comments: “This is really helpful because if it’s difficult to work with in a lab, it’s going to be a nightmare when you’re standing on a scaffold on the ship’s side.”

Initial materials selection

Professor Nicola Symonds carrying out a tensile test on a candidate caulking material

During the first phase of the project, the nC2 team assessed the performance of nine different types of caulking and glue (the sealant between the planks) and five paint systems (including primer and topcoat), using hundreds of oak samples prepared by NMRN’s shipwrights.

“The aim was to find out whether the caulking or glue would provide a watertight seal, whether it would flex with the ship, and how it would fare over time,” says Nicola. “For the paint, it was a case of assessing how well it adhered to the wood, how watertight and flexible it was, and how quickly it degraded with sunlight and salt water. We also looked at how the paint and caulking or glue interacted with each other.”

The team has also been examining candidate materials for the metal fastenings used to secure the planking to see how they will be affected by acidic compounds in the wood, and how well they will withstand the wet and salty environment of HMS Victory. Using CT scanning they are able to view the test fastenings in situ and look for signs of corrosion.

Building on early results

Paint schemes after exposure to UV light and humidity

The results from phase one have enabled the team to select the best performing materials for further phases of testing. Senior Consultant Rachel Triggs explains: “One type of paint worked particularly well so we’re doing a second round of testing with additional paint schemes that have similar chemistries, to see if there’s one that could perform even better.”

As well as testing samples that have been subject to simulated weathering in the lab, the team is gathering evidence from an outdoor exposure rig, set up alongside the ship itself, where samples have been out in the elements for six months. “We’re getting the information from this ‘real environment’ testing, which will help to build a picture of how well the paint and caulking will perform,” says Rachel.

Another aspect of the testing programme is looking at how the use of fungicide – specifically in the form of nanoparticles applied as a spray – could impact on the paints, glues and caulking. Rachel explains: “Fungicide is needed to prevent decay in the ship’s timbers and in turn avoid infestations of deathwatch beetles, which thrive in damp, decaying wood. The use of fungicidal nanoparticles is quite new and there is little knowledge about how they behave, so our aim is to get a greater understanding of how they will affect the different materials.”

Watch Rachel talk about testing the effect of nanoparticles on materials’ behaviour

Collaboration and communication

Dr Spencer Court (UoS) briefs the shipwrights on early results

nC2 takes pride in providing excellent customer service and building strong relationships with its clients, and this project is no exception. “The team are easy to work with and always very helpful – I’m always comfortable emailing them with a question or idea,” says Diana. “They visited the ship to see the challenges for themselves, and have shared some initial results with the shipwrights, giving them a chance to engage with the project and see the outcome of their work.”

Diana adds: “Victory is a much-loved artefact with an amazing history – people know it as Nelson’s flagship at the Battle of Trafalgar but there’s so much more to it than that one battle. nC2’s involvement gives me added confidence that we’ll be able to do our best for this unique ship.”