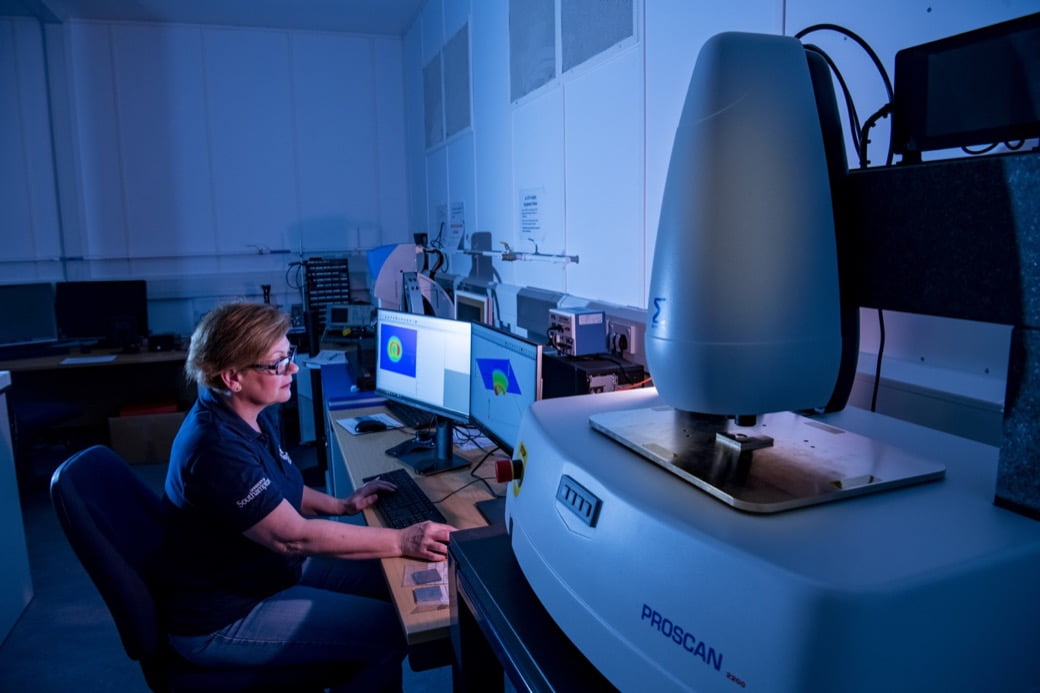

nC² staff normally have full access to the state-of-the-art surface metrology equipment housed at the University of Southampton.

We use our metrology equipment to quantify the finish and form of surfaces provided by our clients. This could be

-

a measurement before and after a wear test or

-

as a confirmation of build during a failure investigation.

As explained in the video below, this access is currently limited; further information about what work is currently taking place can be found on our COVID-19 page.

Please get in touch with us so we can explain how accurate metrology can provide valuable information about your product.

Covid Contact form

2 min video about surface metrology by Dr Nicola Symonds

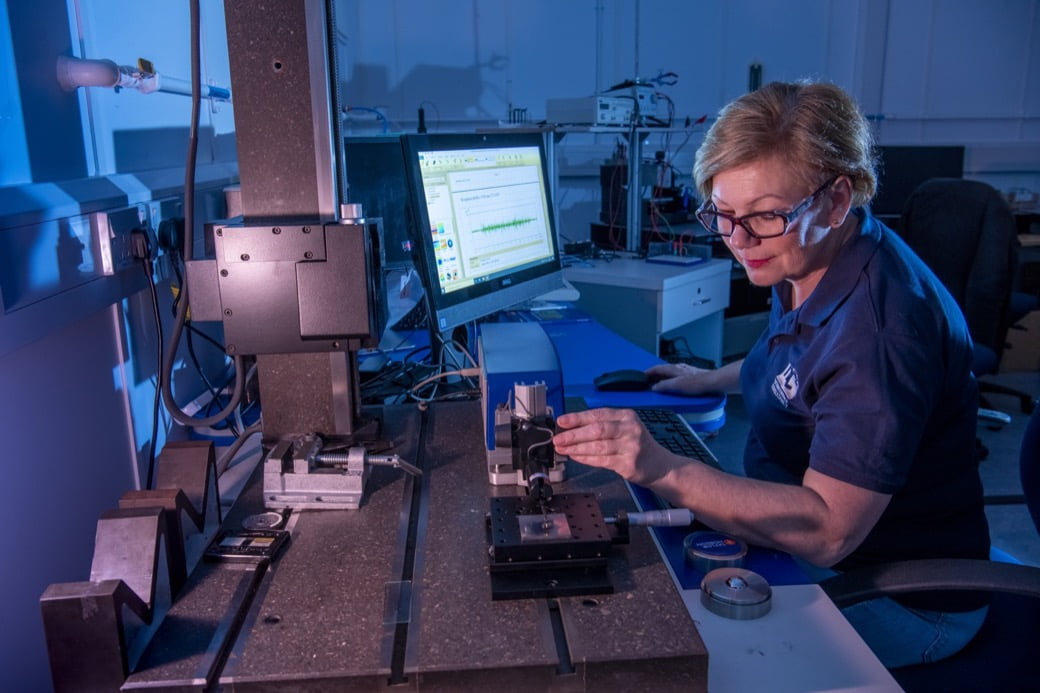

2D surface profilometry

In addition to the miniature Surtronic S125 shown in the video above, we also have a Form Talysurf Intra Touch, which is a semi-portable system for quickly measuring surface finish and form. It also uses a contacting stylus: we have a range of these, including ones to look down bores.

This system is commonly used to measure surface roughness parameters of samples before we begin any wear or friction tests.

2D surface profilometry using the Intra Touch

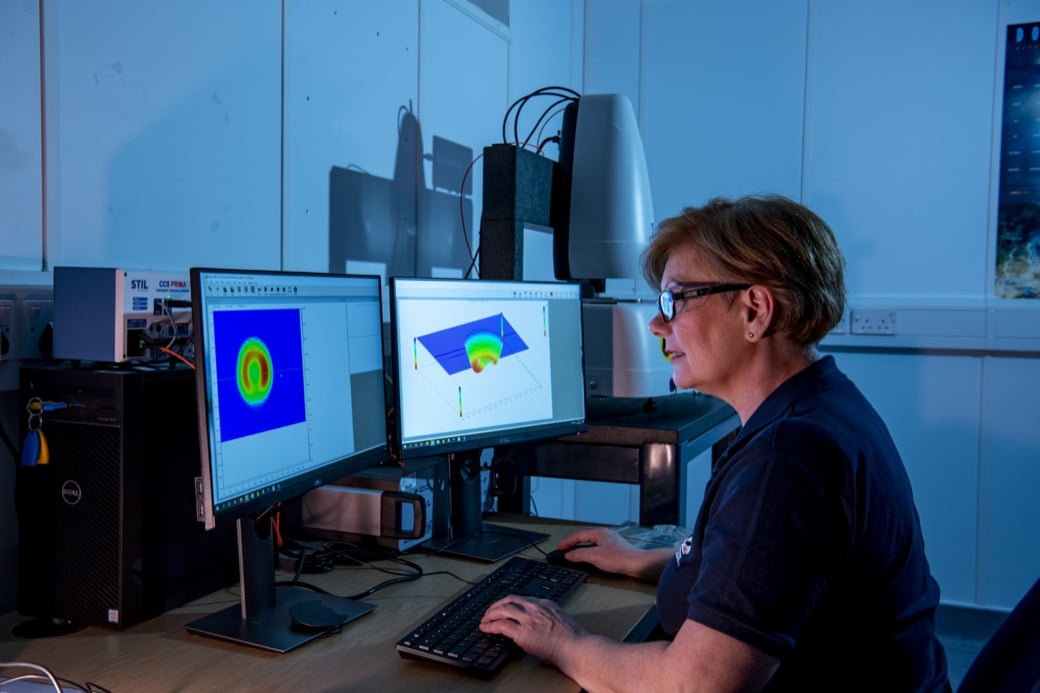

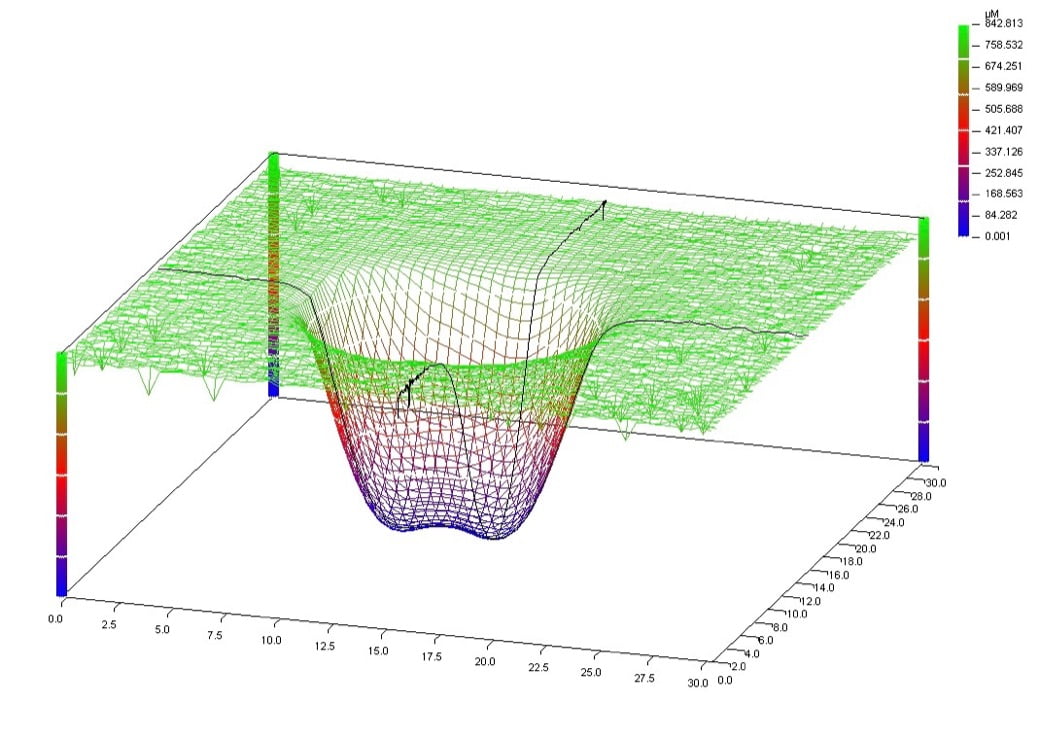

Texture mapping

The Alicona InfiniteFocus 3D mapping system, is a digital microscope with the capability not only to build up a layered image from many ‘slices’, but also to measure contours and surface roughness.

This machine is particularly useful to image and map rough textures such as fracture surfaces, and is a tool we often use when investigating component failures for our clients.

3D texture mapping with Alicona