Introduction

We use the air–sand erosion test to assess the erosion resistance behaviour and rank the performances of various engineering materials; for example, materials for the design and manufacture of gas compressors used in the oil and gas industry. We use the sonic air – sand rig, housed within the laboratory of the University of Southampton, typically to carry out comparative study to assess materials for their erosion resistance performances.

The air-sand erosion rig

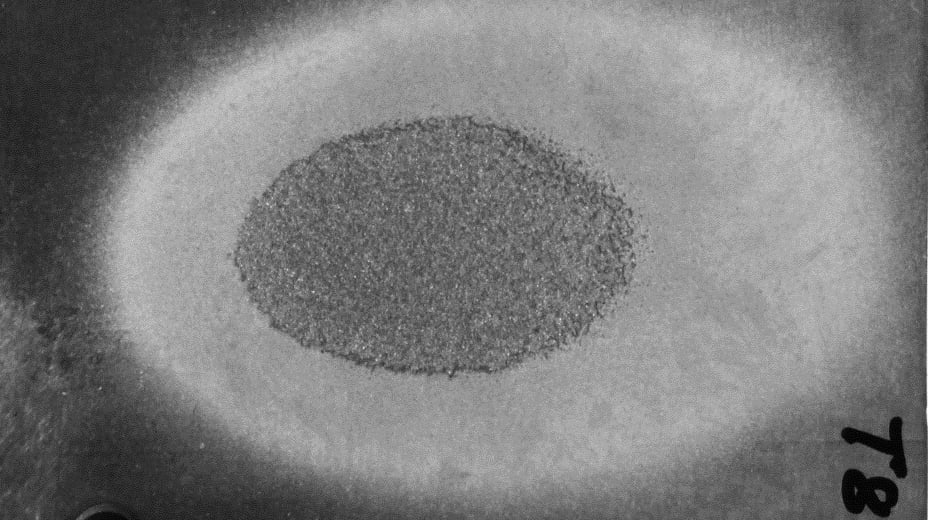

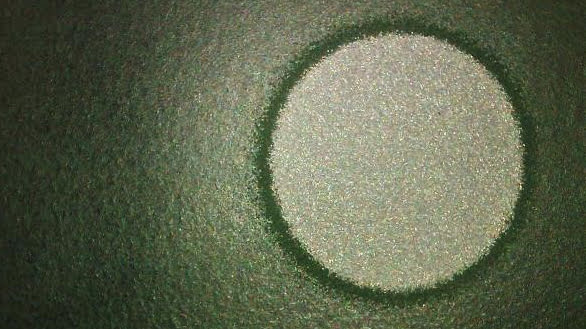

The air–sand erosion rig

We insert the sample into the test chamber and we feed the erodent through the vibrating hopper at the top of the rig. This test conforms to ASTM G76 which states that the samples are removed at known intervals and weighed.

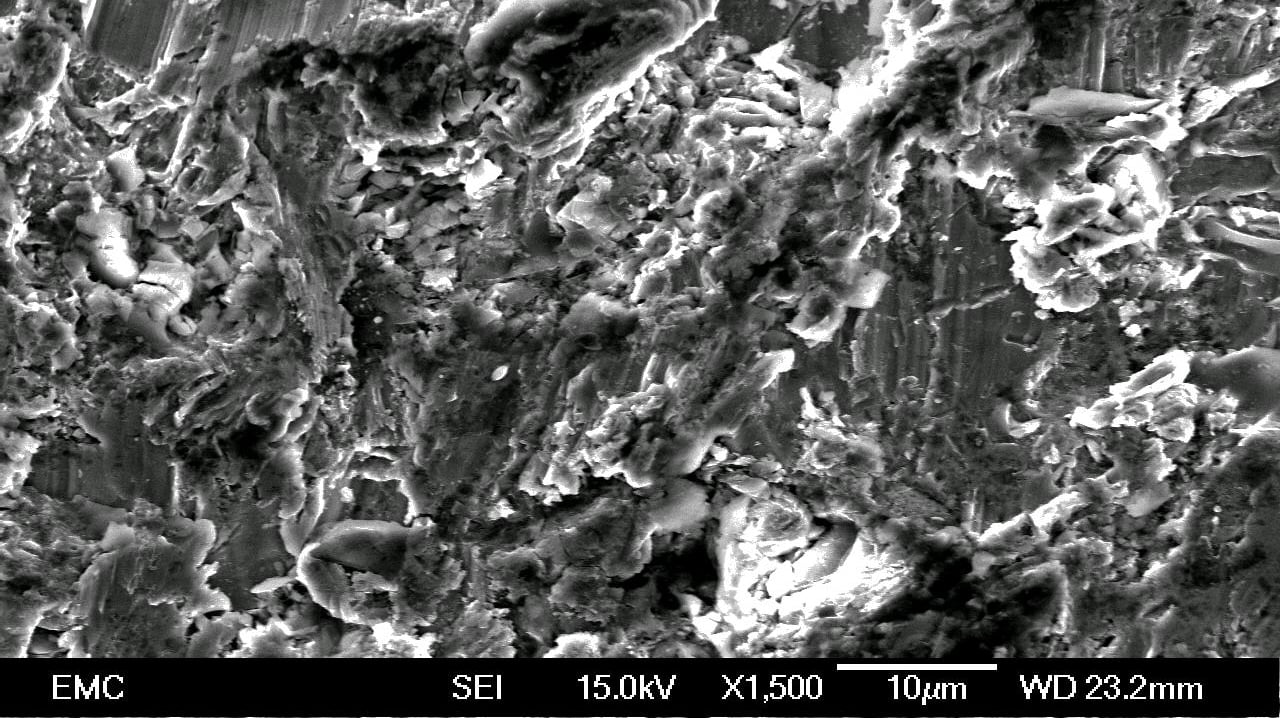

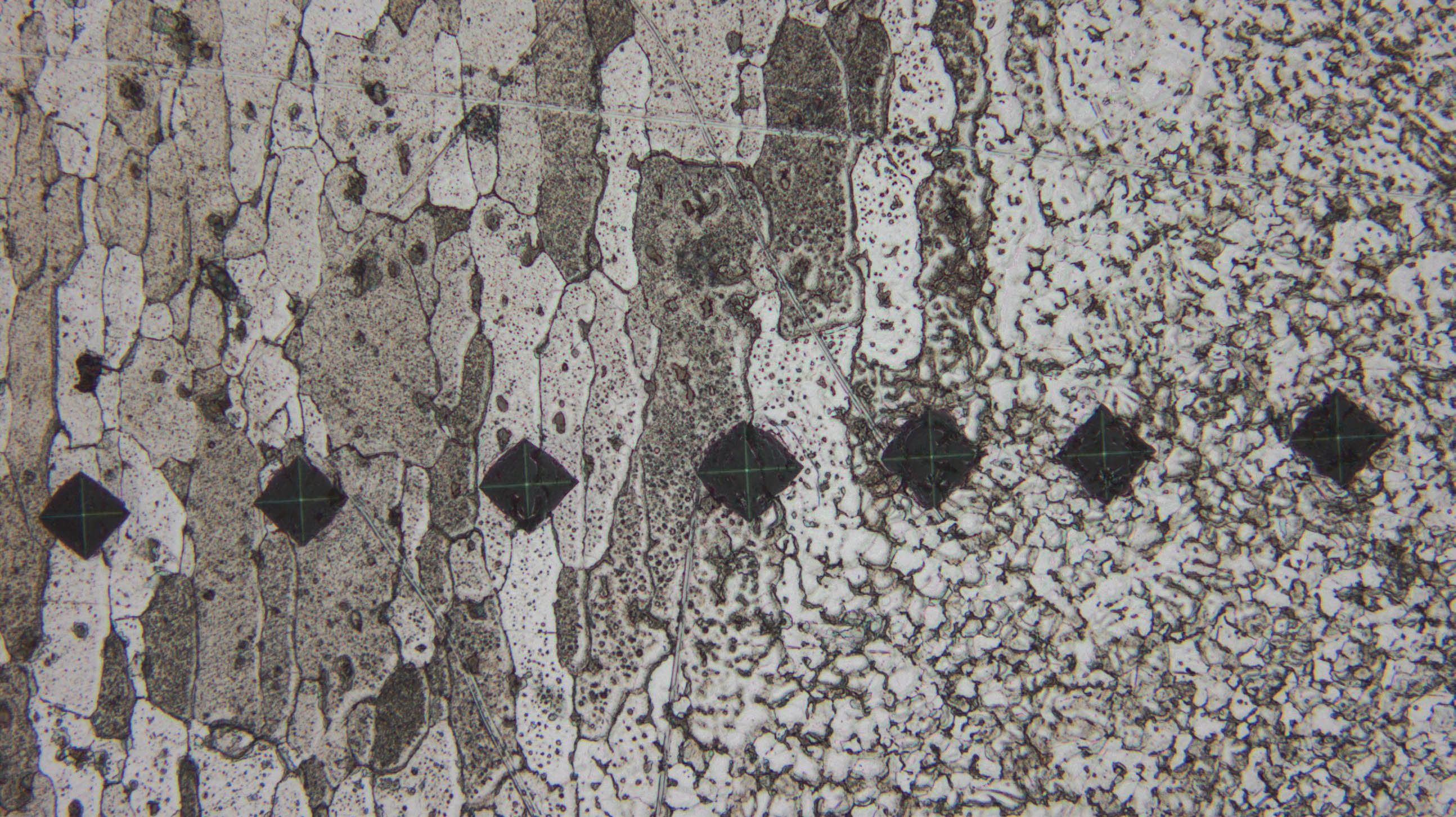

Data analysis of air sand tests

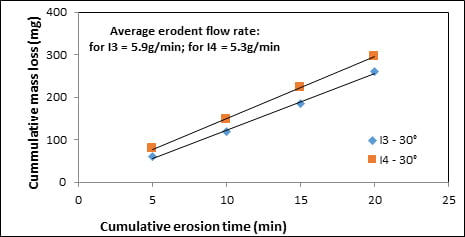

As a post-test analysis for a typical air–sand test, we would plot the cumulative mass loss against cumulative erosion time, after measuring the mass loss at set intervals. The average of the mass loss for each material is calculated, converted to volume loss using the densities of the materials and plotted to assess their overall erosion performances.

Plotting mass loss over time