Understanding the effect of particulate erosive wear on coatings or materials is critical, whether you are developing a new product or looking to optimise existing plant.

Particulate erosive wear is caused by the impact of solid particles against the surface of an object, which gradually removes material from the surface. Our tests and expert analysis will give you insight into how your coatings or materials will perform in specific environments.

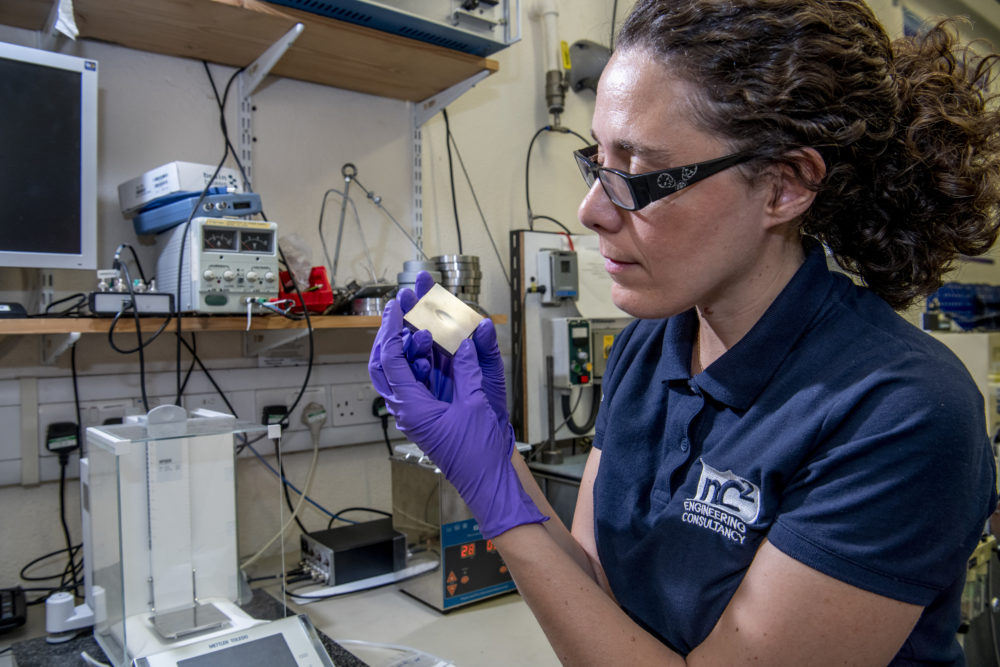

Setting up the slurry erosion test rig

Setting up the air-sand test rig

Our particulate erosive wear testing service

We will work with you to design bespoke tests which simulate the relevant type of particulate erosion, using sand in water or sand in air.

- In our water-sand (slurry jet) erosion test method, we mix sand with water before firing it through a nozzle onto the surface of a material.

- The air-sand erosion test method, which conforms to ASTM-G76, involves adding dry sand to a fast-moving dry air stream and accelerating it down a tube onto a test piece.

For both types of test, samples are subjected to the conditions for a set time. Tests are repeated three to five times to ensure consistency and accuracy.

Post-test analysis

- We weigh each sample before and after exposure to calculate mass loss.

- If we know the material density, we can determine volume loss.

- We can also use 2D and 3D profilometry equipment to measure volume loss directly.

- You’ll receive a comprehensive report detailing the results and our analysis, and we will be happy to discuss the findings with you.

- The results can be used to rank materials or coatings for resistance to erosion under your specified conditions.

Post test analysis

Meet our erosion testing expert

Jelili Bello (JB), Senior Consulting Engineer, is our abrasion and erosion specialist. With more than 16 years’ experience working with industry clients on tribology projects, JB is ideally placed to advise you on the best approach and design the right tests for your needs. Find out more about JB.

Dr 'JB' Bello

What we offer

- Free initial consultation and bespoke quote, which may include free practice tests to determine the best test plan – if you’re not sure exactly what you need, we can advise you.

- A choice of packages to suit your requirements.

- Tests tailored to your needs, run by specialist staff in our state-of-the-art labs.

- A comprehensive report including results and expert advice, plus a meeting to discuss the results.

Why choose nC2?

- A testing service of the highest quality, plus expert analysis of the results.

- Access to highly specialised facilities and knowledge across the University of Southampton.

- Packages to suit your budget and requirements – whether you’re looking for a one-off test or support for a major project.

- Excellent customer service – we’ll keep you in the loop every step of the way.

- High levels of customer satisfaction.