Introduction

WE used the cavitation erosion performance of Nickel 200 to calibrate the equipment at the University of Southampton. We also investigated the incubation period and compared a range of materials, including steel, ceramics, carbide and PEEK.

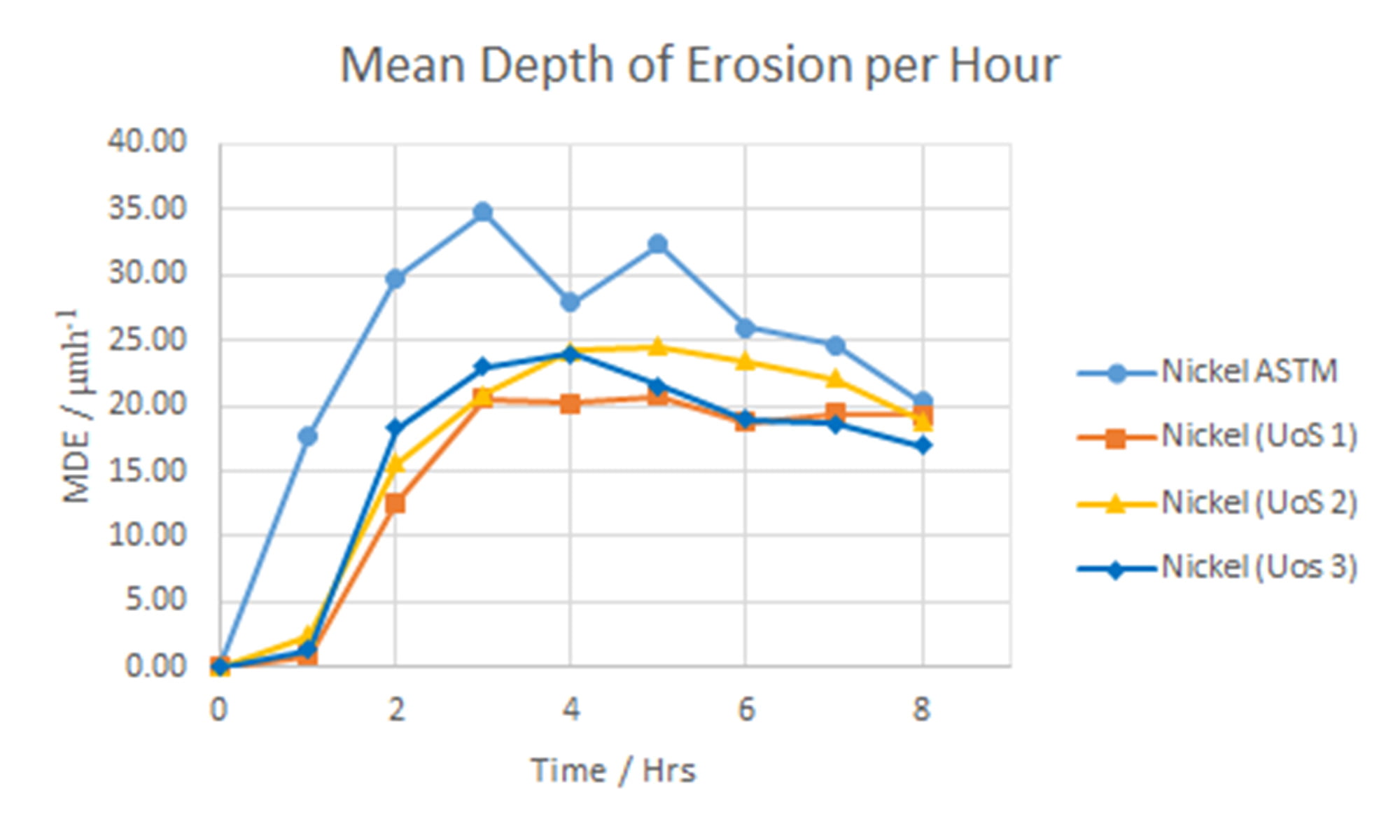

Graph showing the hourly erosion rate

Comparison with ASTM G32

In order to normalise the cavitation erosion test rig with the ASTM G32 standard, we tested Nickel 200 (UNS N02200). We compared the results obtained to the results detailed in Figure 5 of ASTM G32 – 16 [1], which provides cumulative erosion time curves for Nickel 200 to determine a multiplication factor to be applied to normalise results with the standard.

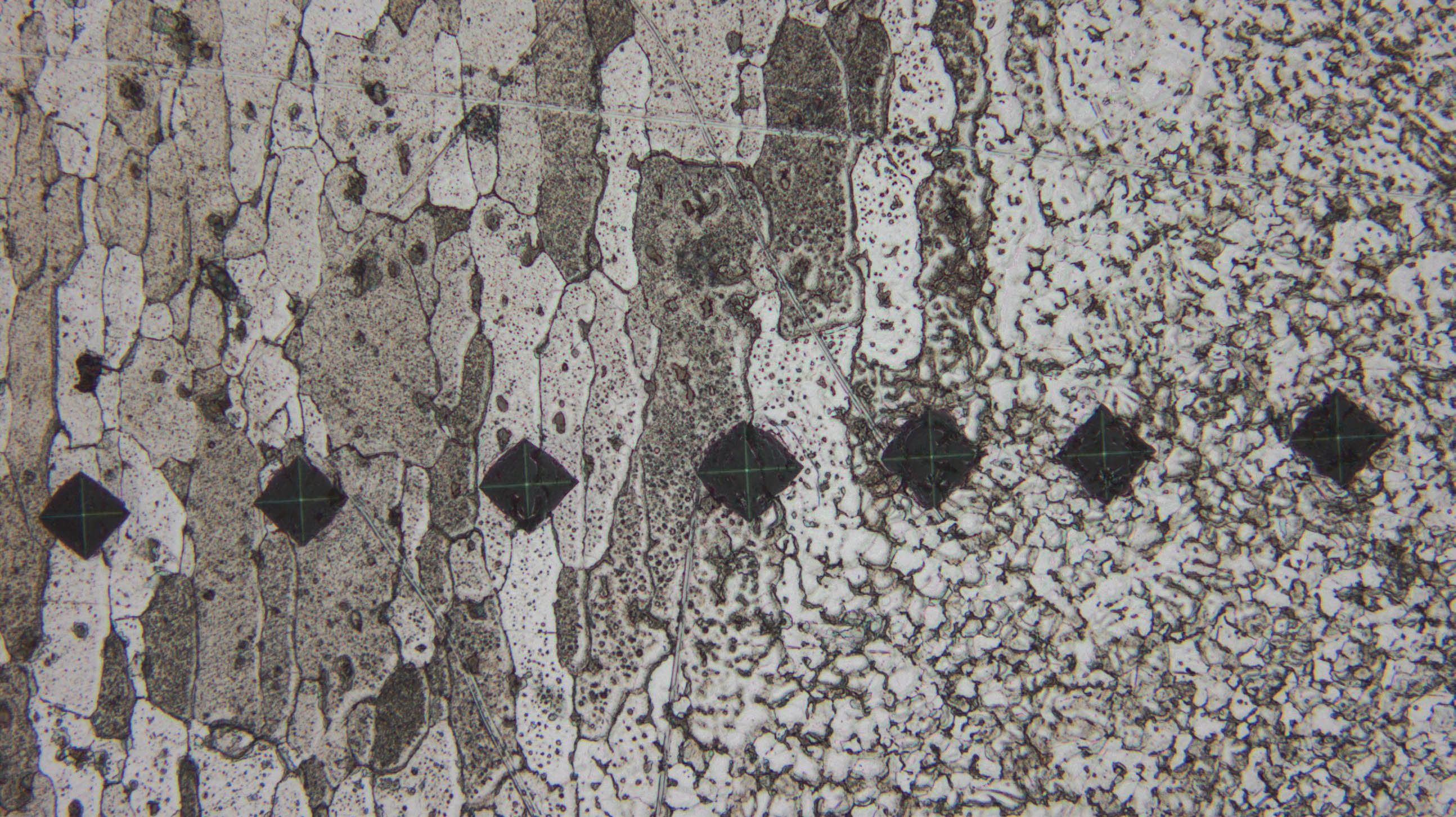

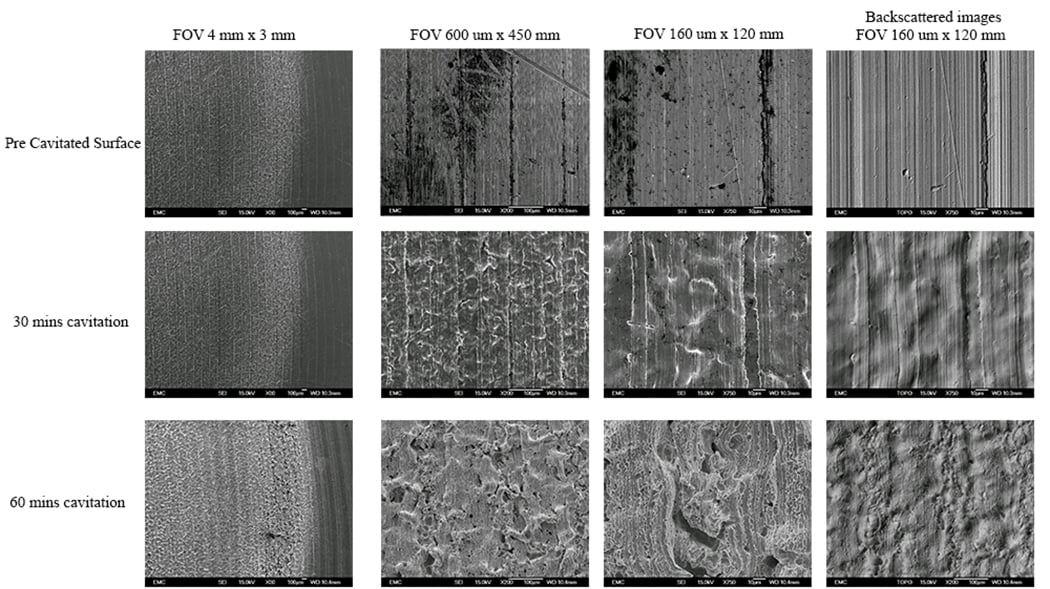

Incubation Period

In order to assess the incubation period, we examined the surfaces employing SEM images after 30 and 60 minutes. The top row of images shows the surface profile prior to testing, where we could clearly see machining lines. After 30 minutes, the surface appears to be indented and this is clearly shown in the backscattered images with the machining line of the original nickel surface following the pattern of the indents. After 1 hour, the fractures on the surface have begun to appear along the machining marks of the original nickel surface, which are still visible.

SEM images during the incubation stage of erosion

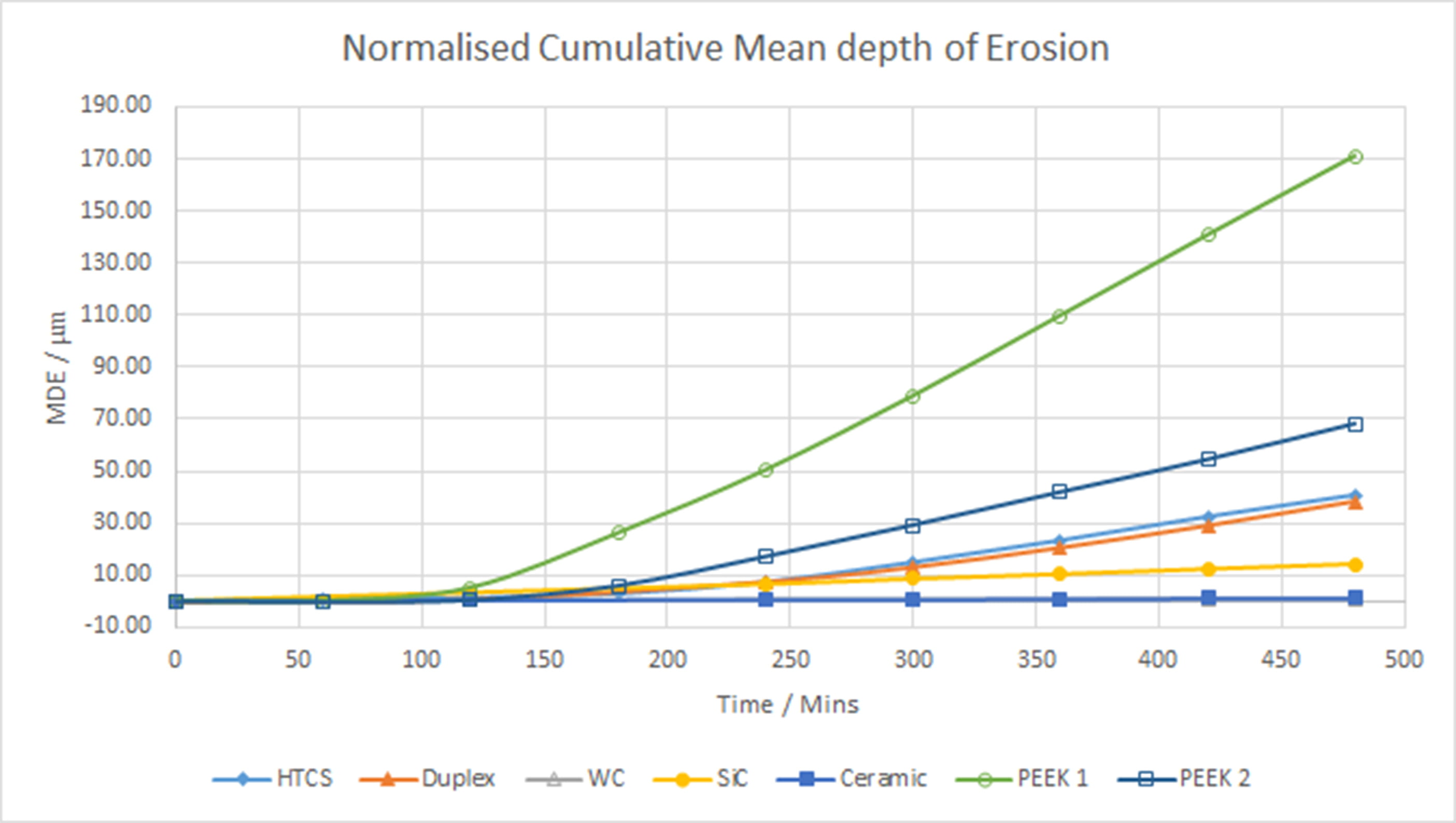

Comparison of Materials

We compared the cavitation characteristics of various materials in order to rank their performance. Materials such as tungsten carbide and zirconia exhibited low rates of erosion, whereas HTCS had a shorter incubation period and a lower maximum rate of erosion compared with duplex stainless steels. We found that the material with the maximum mean depths of erosion was PEEK.

Cumulative mass lass graphs ranking different materials

Further information

You can find further information about this work in the peer-reviewed paper we wrote: “Cavitation Erosion Performance of Steel, Ceramics, Carbide, and Victrex PEEK Materials”, Materials Performance and Characterization, Vol. 7, No. 5,2018, pp. 1093–1106, https://asmedigitalcollection.asme.org/materialsperformance/article-abstract/7/5/1093/1186768/Cavitation-Erosion-Performance-of-Steel-Ceramics?redirectedFrom=fulltext. ISSN 2379-1365