Dr Benjamin Cunningham joined nC² in 2022 as a mechanical test consultant. He is supporting our growing portfolio in this area for both room temperature and cryogenic testing.

As well as professional experience gained at an engineering design consultancy firm, Ben has a BEng in mechanical engineering from the University of Plymouth, a design-based MEng from Bournemouth University, and recently completed an industry-funded PhD at the University of Southampton.

What is your role at nC2?

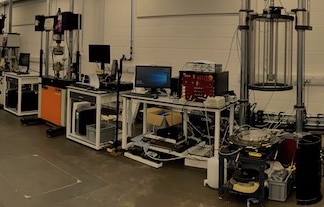

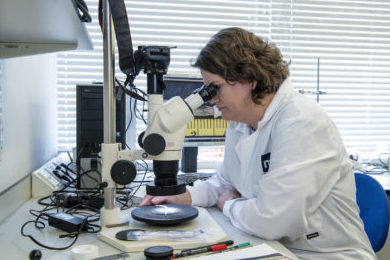

As a mechanical test consultant my main tasks at nC2 are to design and carry out mechanical tests to standards at the Testing and Structures Research Laboratory to aid in failure investigations. In addition, I help support team members on many projects from sample preparation and imaging to data analysis and report writing.

Dr Benjamin Cunningham

So far I’ve been involved in lots of different projects, and developing my knowledge and skills to carry out cryogenic mechanical testing, at temperatures down to 20 degrees above absolute zero, and I’m looking forward to doing that sort of work as it develops. I have had the opportunity to investigate components that have failed in service, which is a side of nC2’s work that really interests me.

I’m able to contribute some additional skills and knowledge from previous roles, including engineering drawing and design – I’ve recently produced some designs for bespoke test rigs – and used finite element analysis, which uses computer modelling to understand how components behave under different conditions.

What did you do before joining nC2?

After finishing my BEng I spent six years at a design consultancy firm, AMTEK Engineering Solutions, which works across a range of sectors and companies including Rolls-Royce, BAE, Sunseeker and many more. During this time, I completed my MEng.

I then did a PhD at the University of Southampton. It was funded by EDF Energy and looked at the problem of cracks occurring in turbine blades. I tested the material to understand the crack growth behaviour, and investigated the efficacy of a mitigation strategy which involved grinding away existing cracks followed by shot peening. The aim was to inform EDF about the typical behaviour they might expect to see and enable them to predict the lifespan of the components.

How has this equipped you for your current role?

My main role at AMTEK included finite element stress analysis to ensure designs conformed to strength specification and relevant standards. It also involved engineering design and drawing, collaborating with colleagues and report writing.

During my PhD I gained insights into an industry challenge and developed a range of skills, including material preparation, fatigue testing, surface characterisation and project management.

These skills, and my industry experience, are all highly relevant to the type of work we specialise in at nC2.

What do you enjoy most about working at nC2?

The culture of teamwork. I think to work well in a team you need to get on with your colleagues – everybody at nC2 is so easy to get along with.

I also like the fact that, as well as bringing new skills, I’m still learning things every day. There’s a lot of variety, so you’re always being challenged.