Finding out exactly why a materials failure has occurred is essential in order to get your product design right and avoid costly repeat issues.

We can identify and interpret fractographic clues, providing you with the evidence you need to understand failure mechanisms.

You’ll benefit from our internationally recognised expertise in failure and accident investigation, plus the insights gained from our extensive experience across sectors such as energy, aerospace, marine and rail.

Our clients include the UK’s Air Accidents Investigation Branch (AAIB), Marine Accident Investigation Branch (MAIB) and Rail Accident Investigation Branch (RAIB), Siemens Mobility Ltd and BAE Systems. Learn more about our accident investigation work.

Our failure investigation service

We have the testing and analysis facilities needed to determine the cause of failure.

Common failure mechanisms include:

- fatigue

- corrosion

- erosion

- cavitation

- fretting

- rolling contact fatigue

- overload

- electrical arcing

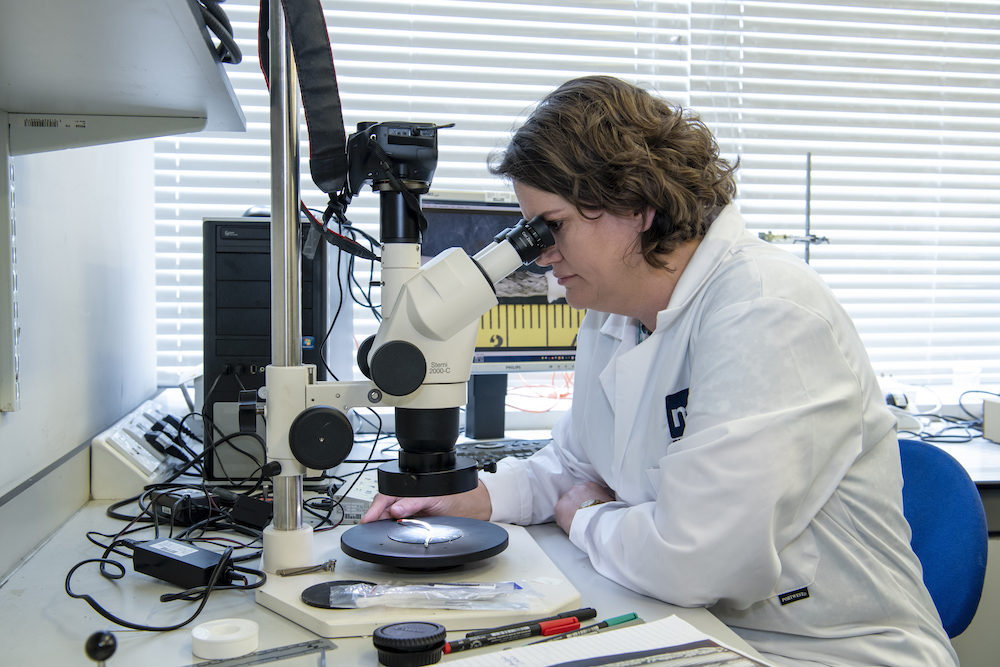

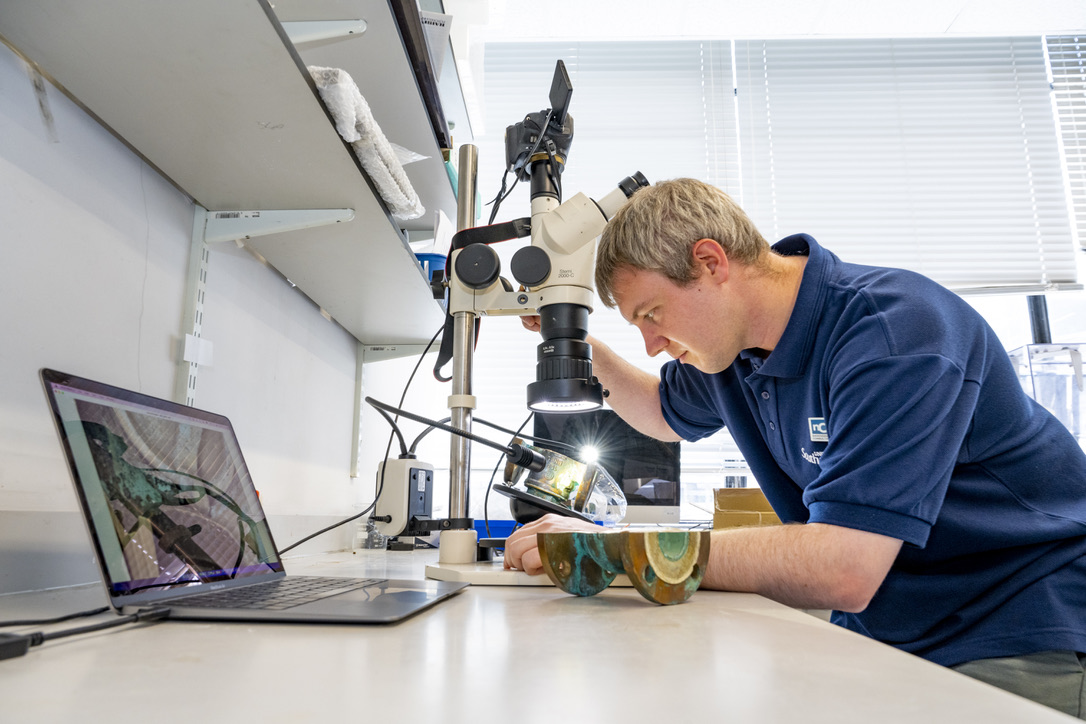

Stereo macroscope examination

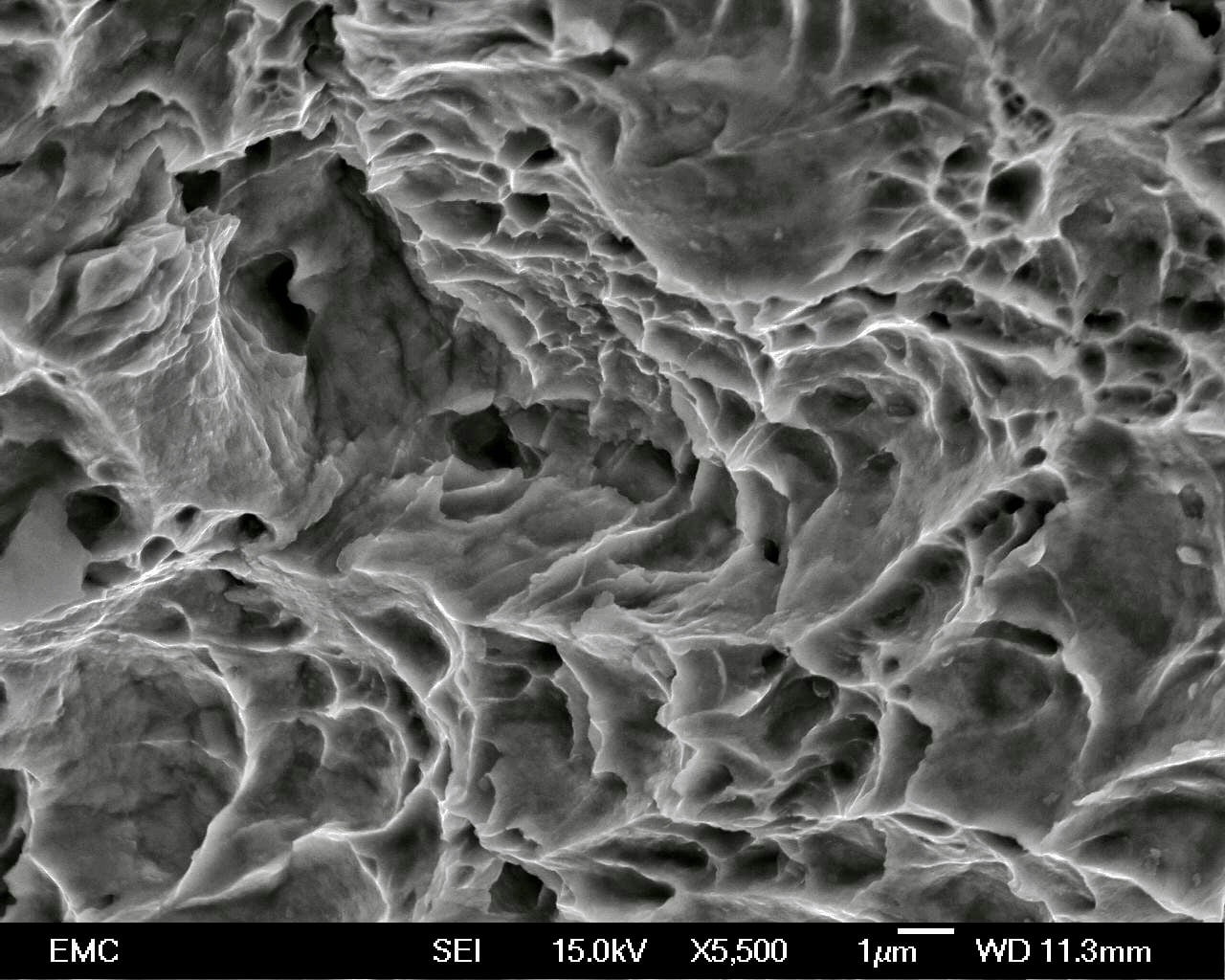

SEM image of ductile dimples on a failed surface

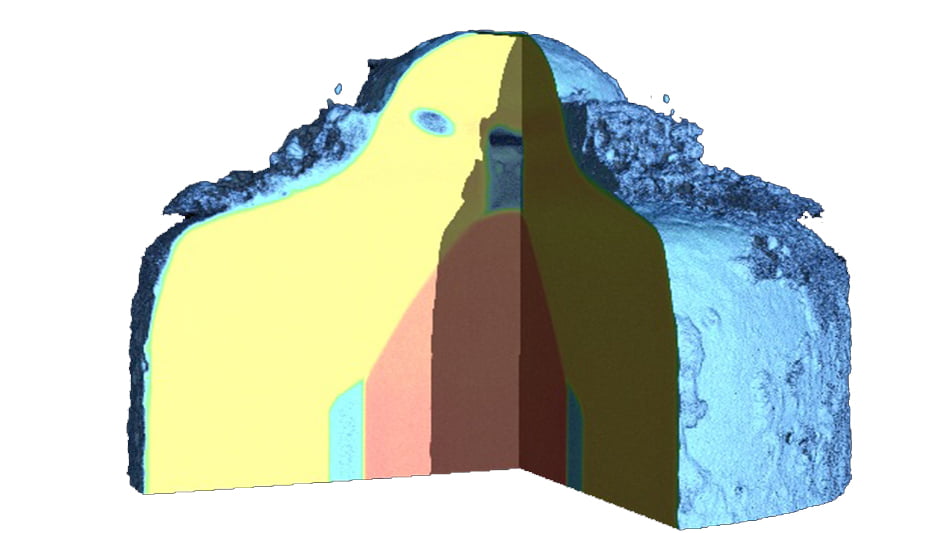

Depending on the nature of your failure problem, the process could include:

- forensic materials engineering

- macro and micro examination

- fractography

- testing of extracted coupon samples

- characterisation and measurement

- CT (computed tomography) for internal failures

- professional opinions and expert witness services

Once we have completed our testing and analysis, you’ll receive a comprehensive report detailing the results and our opinion on the cause of failure. We will also be happy to discuss the findings with you.

Meet our failure investigation experts

Professor Nicola Symonds, Director of nC2, is an internationally recognised expert in the field of forensic materials engineering. She draws on 20 years’ experience, including 10 years working on accident investigations at the Ministry of Defence, and projects for each of the government’s transport accident investigation agencies. Find out more about Nicola’s failure investigation expertise.

Professor Nicola Symonds

For projects involving fibre-reinforced composites we call on the expertise of Dr Meisam Jalalvand, who is a specialist in the characterisation and analysis of these complex materials. He is skilled in using both numerical modelling and sample manufacturing and testing to characterise and understand the failure mechanisms associated with fibre-reinforced composites. Find out more about Meisam.

Dr Meisam Jalalvand

Complementing nC2’s testing and analysis, Professor Mark Young can bring his extensive human factors expertise to our investigations. Human factors looks at the interactions between people and the systems in which they work, and can help our clients gain a deeper understanding of why things went wrong to inform more effective mitigations. Find out more about Mark.

What we offer

- Free initial consultation and bespoke quote, which may include free practice tests to determine the best test plan – if you’re not sure exactly what you need, we can advise you.

- A choice of packages to suit your requirements.

- Tests tailored to your needs, run by specialist staff in our state-of-the-art labs.

- A comprehensive report including results and expert advice, plus a meeting to discuss the results.

Why choose nC2?

- An investigation, testing and analysis service of the highest quality.

- Access to specialised facilities and knowledge across the University of Southampton.

- Packages to suit your budget and requirements – whether you’re looking for a one-off test or support for a major project.

- Excellent customer service – we’ll keep you in the loop every step of the way.

- High levels of customer satisfaction.