Mechanical testing is an essential part of product development, or can help you get to the bottom of failure-related problems.

We offer access to world-leading mechanical testing facilities and expertise through our partnership with the Testing and Structures Research Laboratory (TSRL) at the University of Southampton.

Using these facilities we can put your material or component through its paces, then analyse the results to gain the insights you need. This could be in combination with other nC2 services such as failure investigation or environmental testing.

For example, you might be seeking to:

- find out how a new material will behave when different forces are applied under different temperatures, and therefore whether it is right for your product

- evaluate a new product’s performance at prototype stage

- understand what has caused a component to fail, enabling targeted remedial action

In collaboration with our TSRL colleagues we will design and run a bespoke package of tests to meet your requirements and offer expert opinion on the results.

Mechanical testing facilities

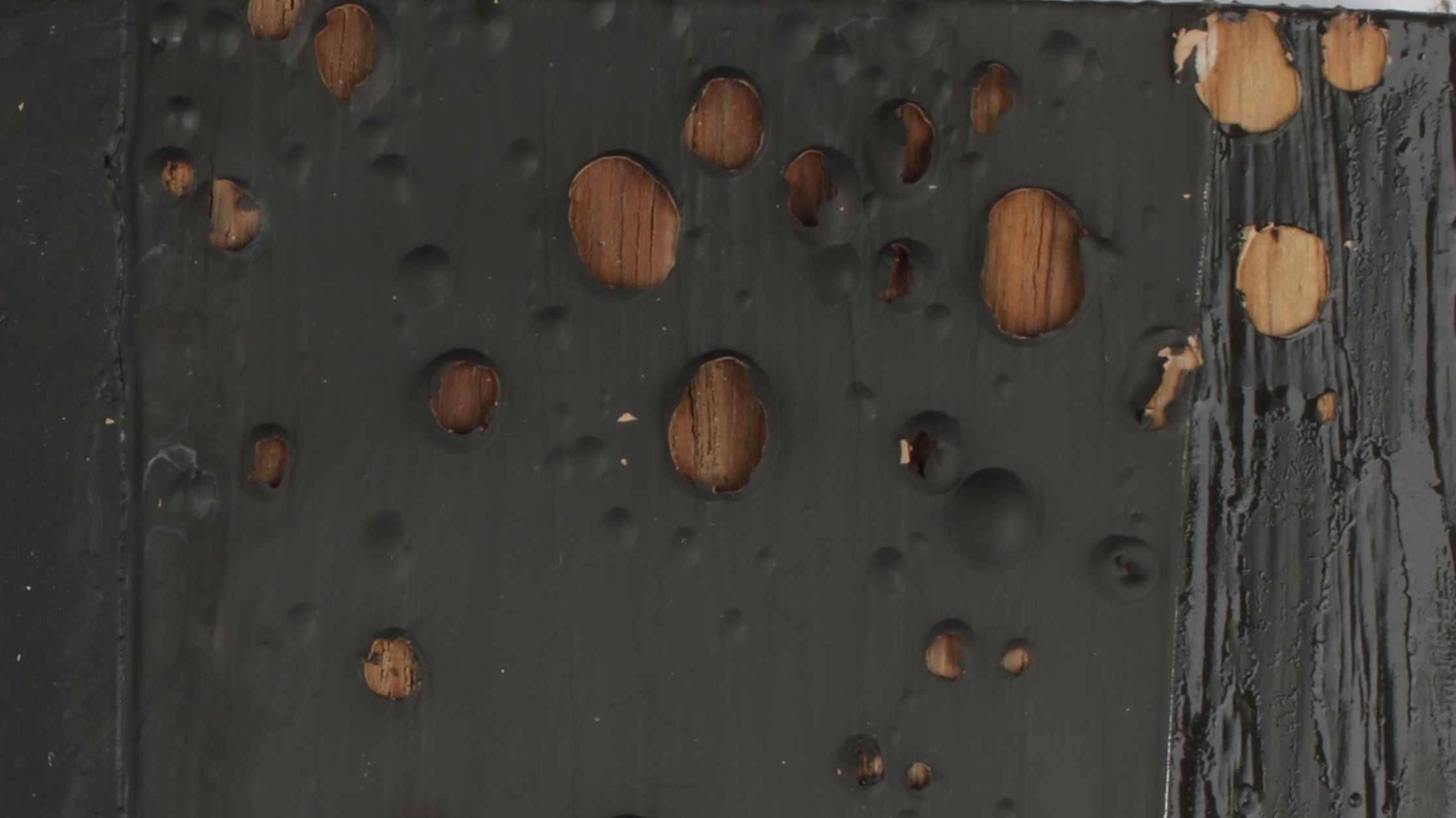

The TSRL’s suite of testing equipment offers an exceptional breadth of capability; we can apply tension, compression, torsion and bending across the loading scales, length scales, temperature scales and strain rates.

For example, we can:

- apply force ranging from a few newtons up to 630kN

- test at low or very high strain rates

- test at temperatures from minus 200°C to plus 1,000°C

- accommodate sample sizes up to approximately 1m, with access to the University’s Large Structures Testing Laboratory for larger samples

- build a full-field picture of stress and strain using specialist imaging techniques (including digital image correlation)

- use 3D high-resolution digital image correlation (DIC) to obtain full strain fields in mechanical tests

Take a video tour of the TSRL’s facilities

Test using a hot chamber

Post-test analysis

As well as analysing the test data, we can select from a range of non-contacting, non-destructive imaging techniques to identify and quantify damage and defects within structures and components.

We can also run full DIC analysis to extract rich datasets of 3D strain fields and validate component behaviour.

Once the testing and analysis is complete, you’ll receive a comprehensive report detailing the results, which we’ll be happy to discuss with you.

Meet our mechanical testing experts

Professor Nicola Symonds, Director of nC2, takes the lead on designing mechanical testing packages for our clients, drawing on her extensive experience to identify the relevant specifications and parameters to get the answers clients need. She and her nC2 colleagues are also experienced in running the tests, after which they process the data and report on the findings. Find out more about Nicola.

Professor Nicola Symonds

Dr Benjamin Cunningham joined nC² in 2022 as a mechanical test consultant to support the growing work we have in this area for both room temperature and cryogenic testing. Find out more about Ben.

Dr Benjamin Cunningham

We also call on the expertise of Dr Andrew Robinson, Principal Experimental Officer at the TSRL. A specialist in mechanical testing and imaging techniques, Andrew knows the lab’s equipment and its capabilities inside out, and uses this knowledge to programme the rigs and validate the test set-up. With 15 years’ experience in the field, he’s also our go-to person for guidance on more complex or unusual test requirements. Find out more about Andrew.

Dr Benjamin Cameron is a specialist in digital image correlation (DIC) – a technique for measuring full strain and deformation fields which extracts extremely rich datasets from mechanical tests. He can provide in-depth insights into material behaviour for a range of outcomes, including component validation, high-throughput materials development or enhancing digital simulations. Find out more about Benjamin.

Dr Benjamin Cameron

For projects involving fibre-reinforced composites we call on the expertise of Dr Meisam Jalalvand, who is a specialist in the characterisation and analysis of these complex materials. He is skilled in designing coupon or component tests and interpreting the data to give our clients insights into the properties and behaviours of fibre-reinforced composites. Find out more about Meisam.

Dr Meisam Jalalvand

What we offer

- Free initial consultation and bespoke quote, which may include free practice tests to determine the best test plan – if you’re not sure exactly what you need, we can advise you.

- A choice of packages to suit your requirements.

- Tests tailored to your needs, run by specialist staff in state-of-the-art labs.

- A comprehensive report including results and expert advice, plus a meeting to discuss the results.

Why choose nC2?

- An investigation, testing and analysis service of the highest quality.

- Access to specialised facilities and knowledge across the University of Southampton.

- Packages to suit your budget and requirements – whether you’re looking for a one-off test or support for a major project.

- Excellent customer service – we’ll keep you in the loop every step of the way.

- High levels of customer satisfaction.