The impeller was from one of three main high pressure sea water pumps that maintain a constant supply of high pressure sea water piped around the ship. The impeller is driven in rotation by a shaft and the liquid between the blades rotates and is subjected to a centrifugal force; it will therefore flow radially from the centre of the impeller to the outer edge, if it is not opposed by a pressure at the outlet.

Damaged impeller

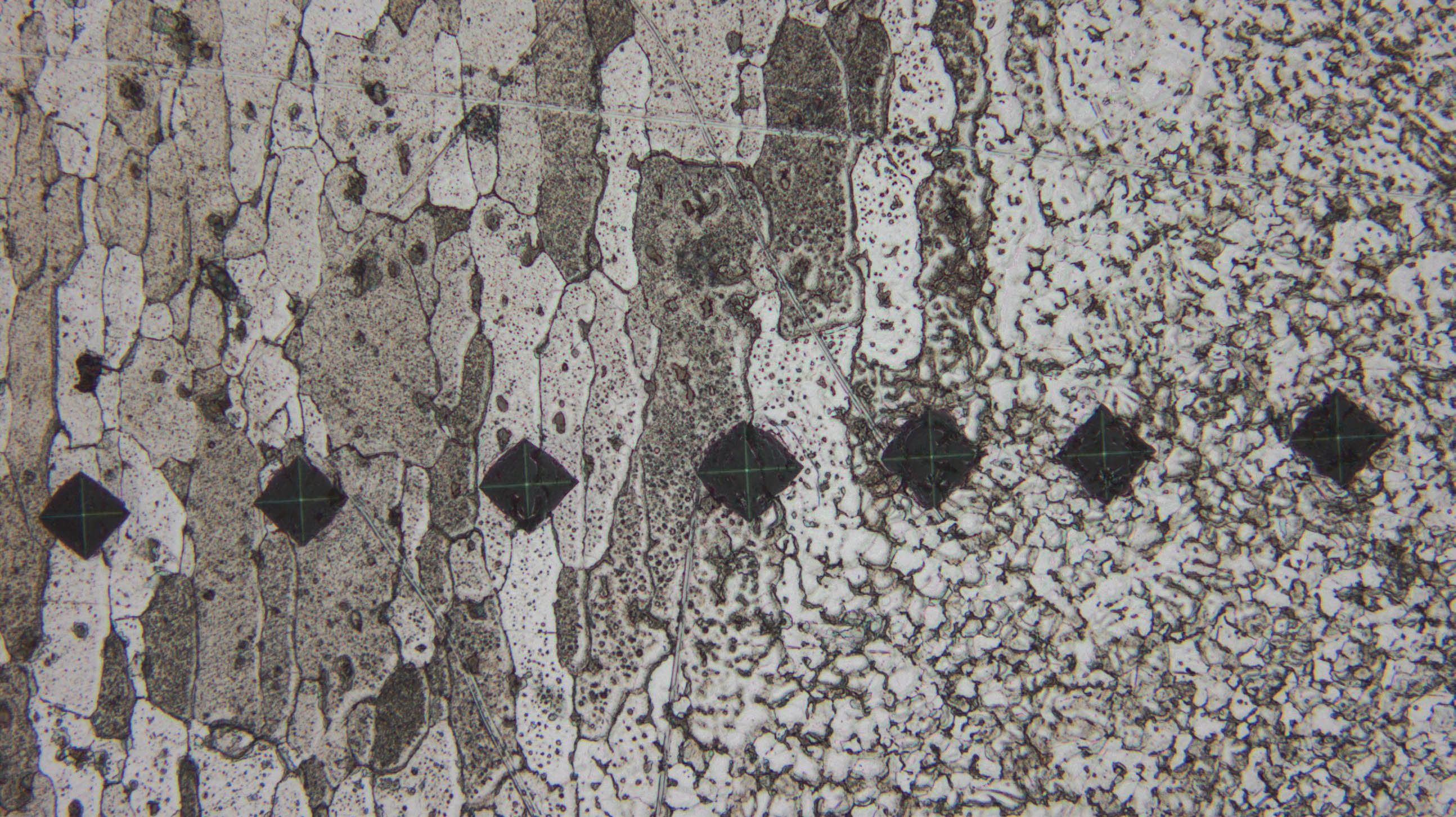

The impeller comprises seven blades and five balancing holes. The balancing holes showed evidence of severe wear. The leading edges of each of the blades displayed thinning and wear and the blades and the back sloping surface that blended into the central key way collar were rough with pitting holes.

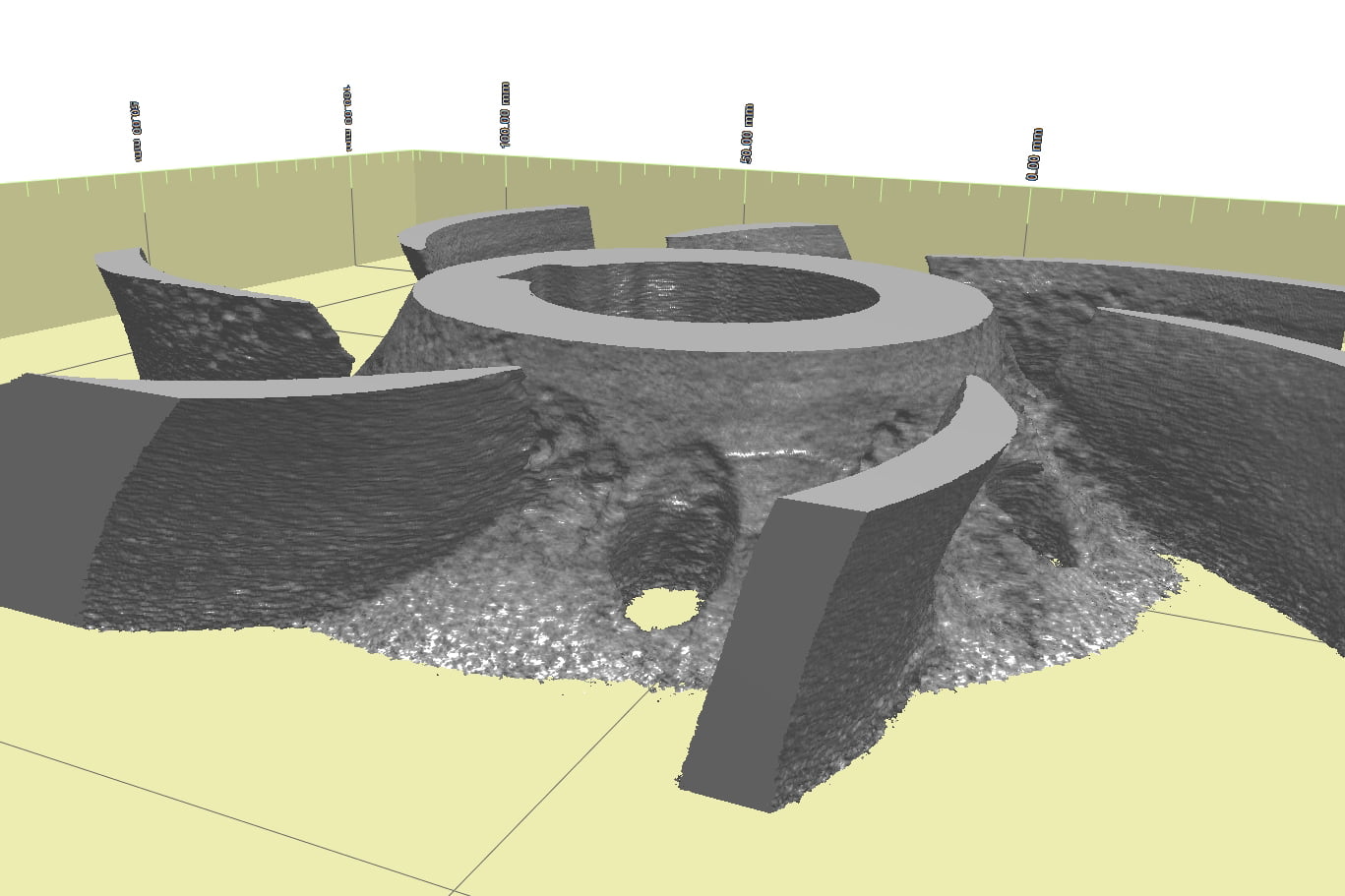

We employed µ-CT (computed tomography) to examine the damage on the blades, as it was deemed they constituted the part more heavily affected by wear. We created a 3D volume of the impeller without the suction and discharge flanges. We could then examine all the surfaces by circling around the virtual space and assess the damage without the need for destructive cutting.

The 3D volume clearly displayed the extent of pitting damage on the blades. By observing the high detailed view of the morphology of the damage, we could identify interesting features revealing clear evidence of severe localised cavitation attack. Using this non-destructive technique, we were able to determine that vaporization cavitation was the dominant mechanism occurring in the failure of this impeller.

CT scan of impeller