The problem

We investigated using μ-CT two injectors from a V12 marine diesel engine. Injector A2 showed a significant amount of contamination on its tip and would open only when a pressure of 280 bar was applied while injector B2 would not open even applying a pressure of 400 bar.

The A2 injector

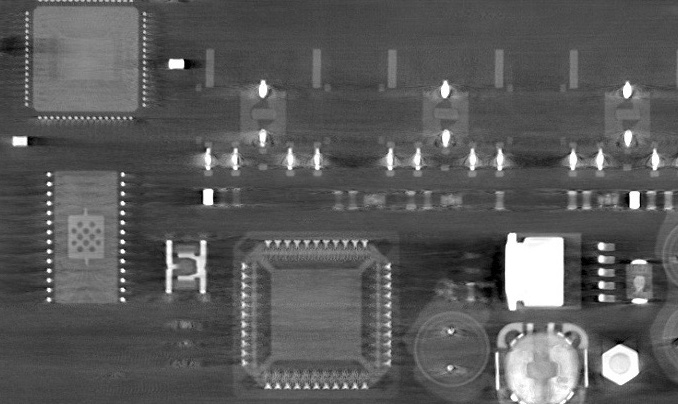

We scanned the tip area of the contaminated A2 injector and produced a 3D volume. We then ‘virtually’ sliced this 3D volume to determine the extent of the contamination. The scan clearly showed that the density of the contaminant (blue) was significantly lower than that of the metallic nozzle tip (yellow) and needle (pink). From a single slice we could unmistakably determined that four nozzles out of eight were significantly blocked by a deposit which had solidified across its surface. This deposit would hinder the release of fuel and therefore we determine that it was the cause explaining the malfunction of this injector. µ-CT confidently resolved this problem; if the tip was cut to be embedded, part of the deposit could have broken down partially destroying crucial evidence compromising the investigation.

A scan of the tip

B2 Injector

The B2 injector

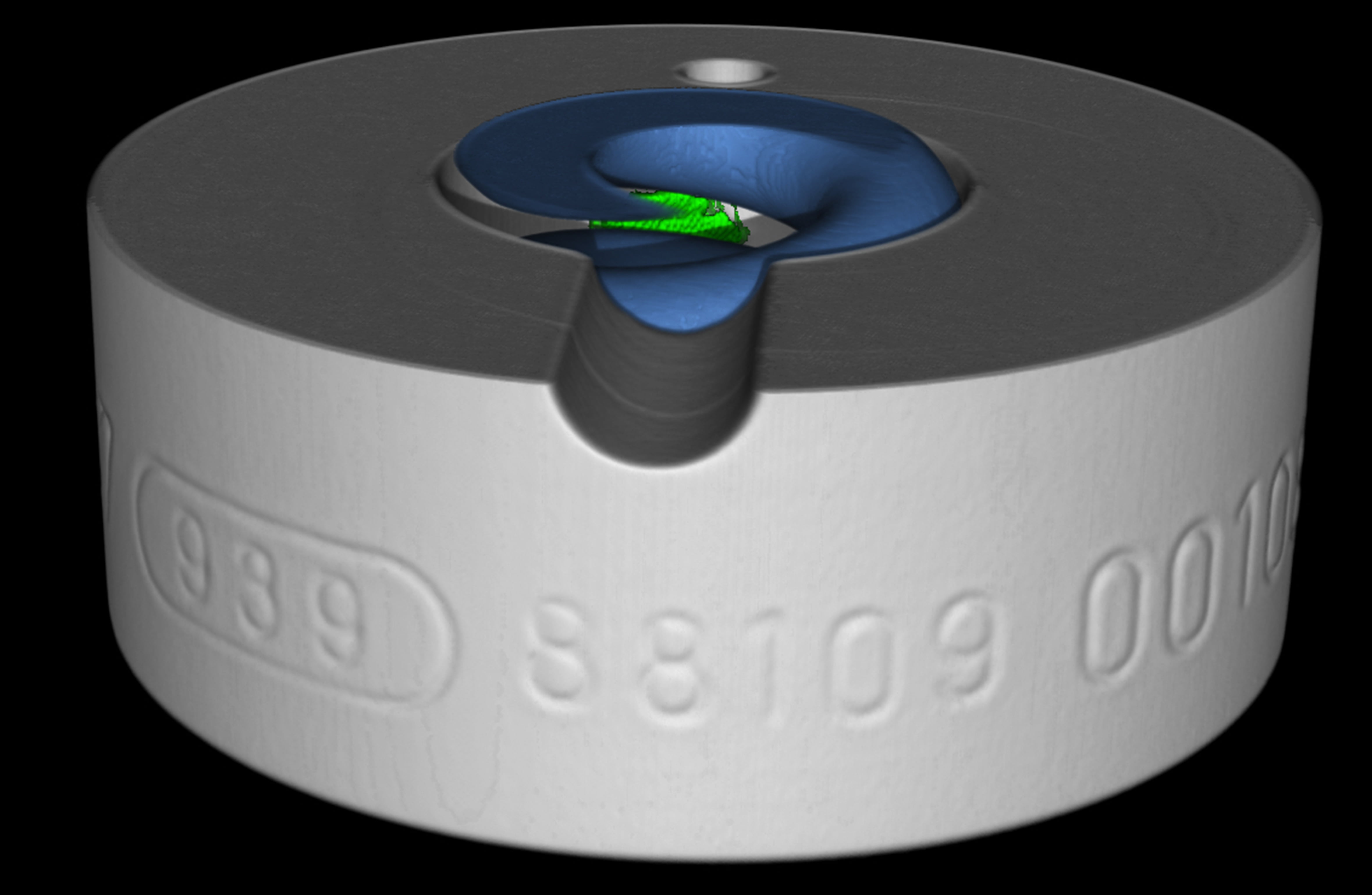

The B2 injector was inoperable, a fast scan revealed a spring-loaded needle valve that closed or opened the nozzle holes. We hypothesized that a spring failure of some form could prevent the correct operation of the injector and we noted a shadow in the scan of the B2 injector adjacent to one of the active coils of the spring. We then performed a higher resolution scan revealing the suspected foreign object (green). This was flake shaped with its shortest side (through thickness < 0.5 mm) in the radial direction of the spring and the longest (> 2 mm) following the circumference of the coil preventing the operation of the needle valve.

The cause

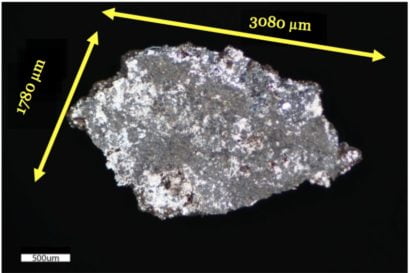

Directed by the CT data, we carried out a destructive strip and examined the injector sub-assemblies. Upon opening of the injector, we found a flake of debris of size 3 mm x 1.8 mm x 0.4 mm.

Image of debris found in the tip