CT is a non-destructive, volumetric imaging technique, which offers a unique perspective that can help to understand what’s going on inside a product, component or material.

Calling on the expertise of our specialist colleagues at the µ-VIS X-Ray Imaging Centre, part of the National Facility for X-ray CT, we can integrate their CT findings into the broader engineering context of your investigation.

For example, you might be interested in:

- failure investigation – what has gone wrong with a product or component, and why

- materials characterisation, for example to understand how a material behaves at different temperatures or under different loads, or to determine the effect that different parameters have on the manufacture of a material

- time-resolved (4D) CT to look at change or damage over time via in situ experiments, or ex situ CT (scanning between test intervals)

- comparison between a newly manufactured product and an equivalent that has been in service

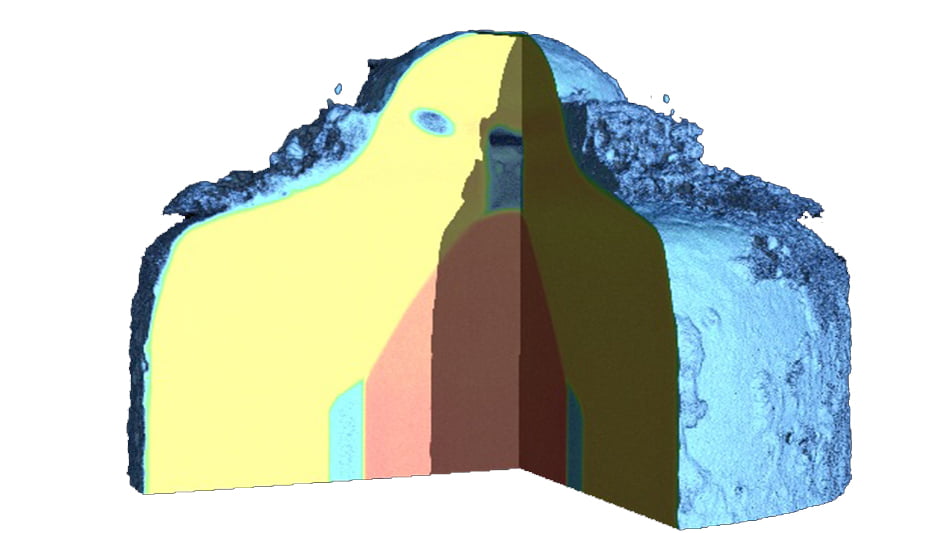

Often the CT scan data itself will provide the evidence we need to identify the cause of a crack, break or failure. CT can be used to pinpoint the optimum position for a physical cross-section of the sample where this is necessary, as we did when investigating an injector failure, for example.

CT scanning facilities

µ-VIS is home to a suite of state-of-the-art micro-focus X-ray CT systems and image analysis capabilities, supporting a wide range of samples up to 1 x 1 x 1.8 m, and spatial resolutions down to 700 nm (in smaller specimens). The suite of scanners and extensive experience of the µ-VIS Centre ensures that an exceptional range of engineering structures can be investigated.

Scanners regularly used for industry projects include:

- the highly versatile Custom 450/255 kVp Hutch: the first scanner of its kind and one of the largest high energy micro-focus CT scanners within an academic institution in Europe

- the Zeiss 160 kVp Versa 510: capable of submicron resolution scanning

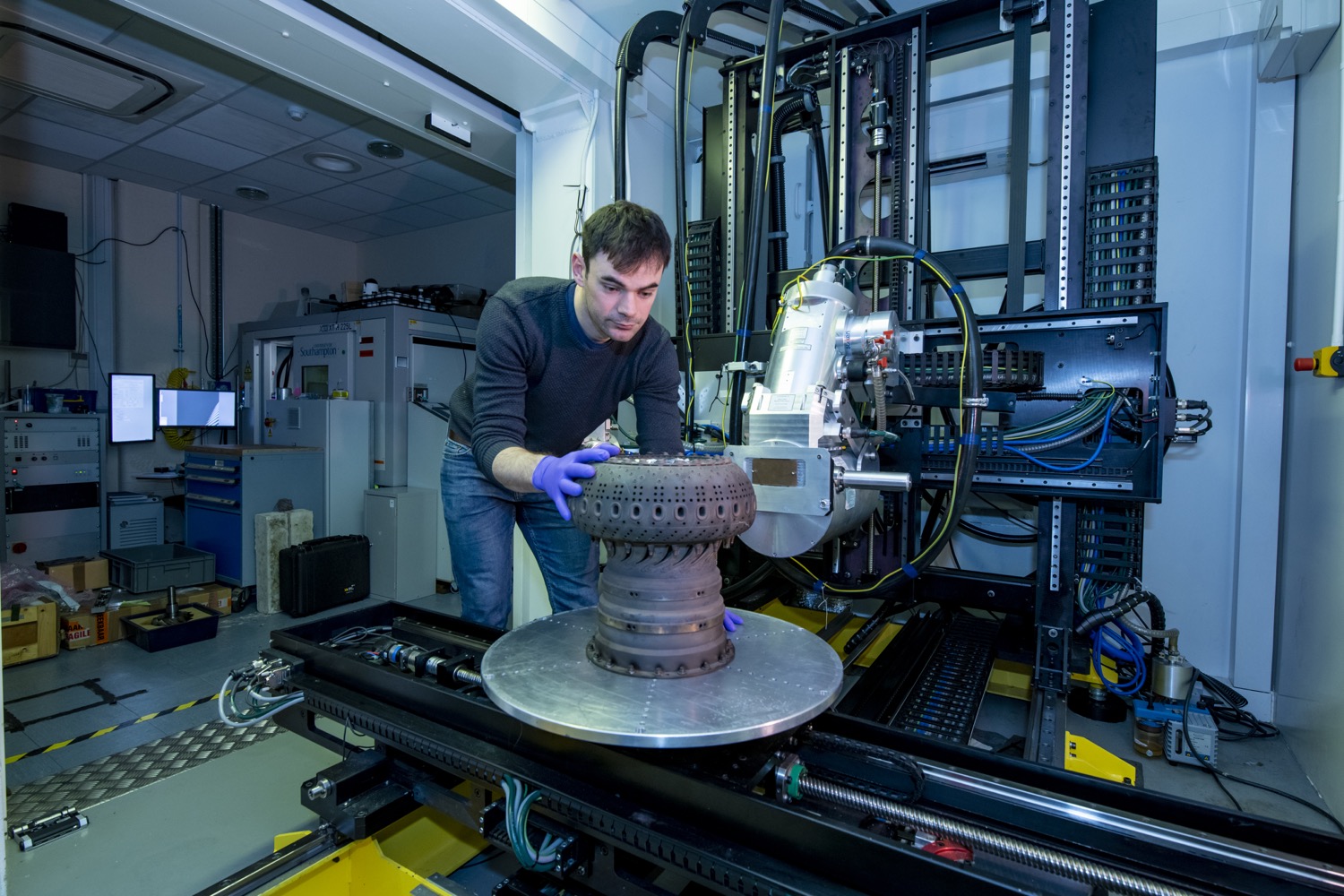

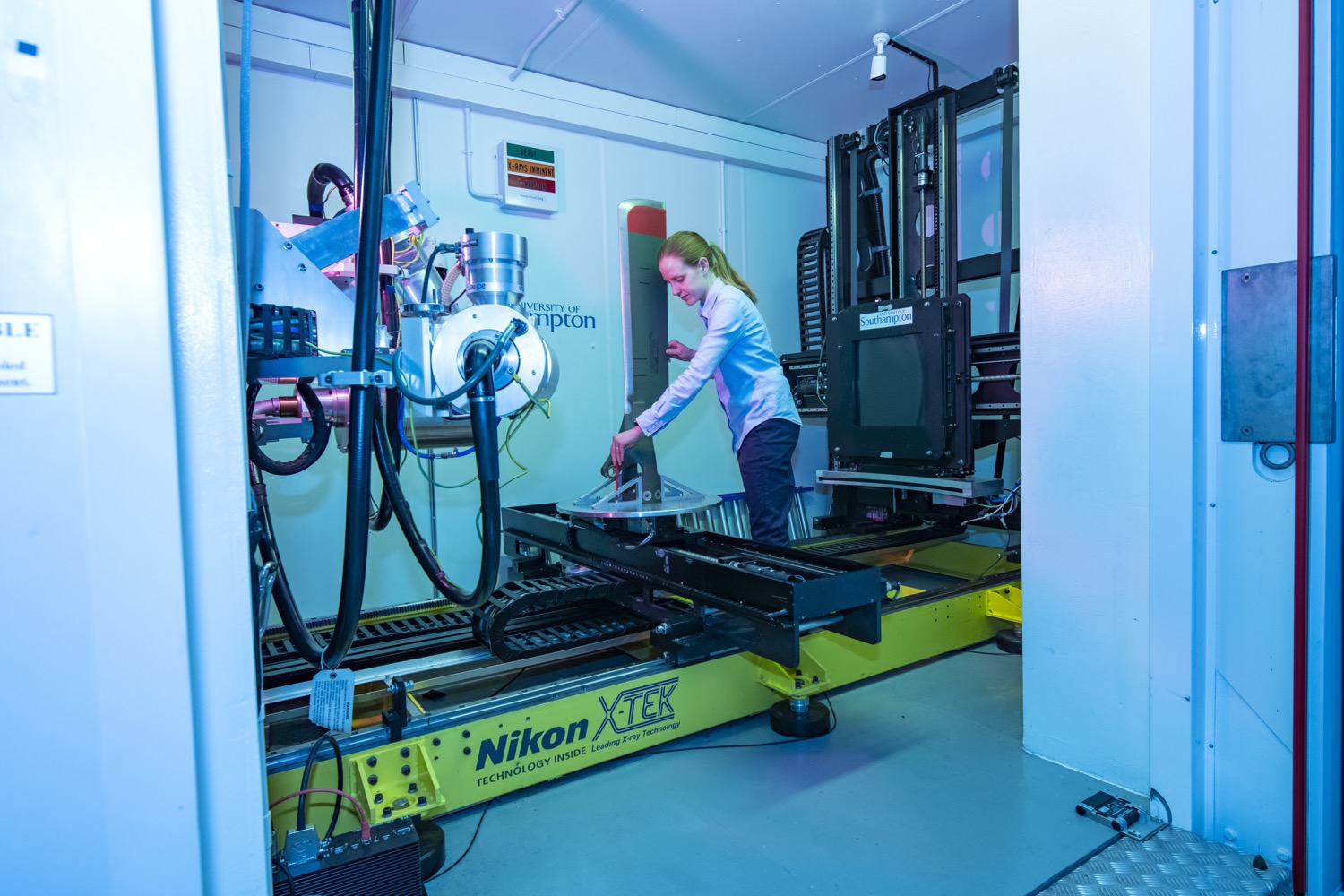

Positioning a sample in the µ-VIS X-Ray Imaging Centre

Setting up a component to scan with CT

Capabilities across the range of CT scanners include:

- 2 x large walk-in scanners, each with two X-ray sources (225kVp micro-focus and 450kVp microfocus, 300 kVp micro-focus and 450 kVp mini-focus)

- panel shifting system, up to 1 x 1 x 1.5 m imaging volume

- scatter reduction imaging modes for dense structures

- large labyrinth allowing cables/hoses etc to be fed into enclosure

- bespoke in situ test rigs (thermal, mechanical etc)

- sub-micron spatial resolution and phase-enhanced contrast capability

- specialist facilities for biomedical imaging

- high-performance computing for data processing and analysis

CT data analysis

Once our colleagues in µ-VIS have processed the data, our experts at nC2 will interpret the CT volume to identify and assess features of interest. In consultation with µ-VIS, we develop bespoke image analysis for quantification from CT data.

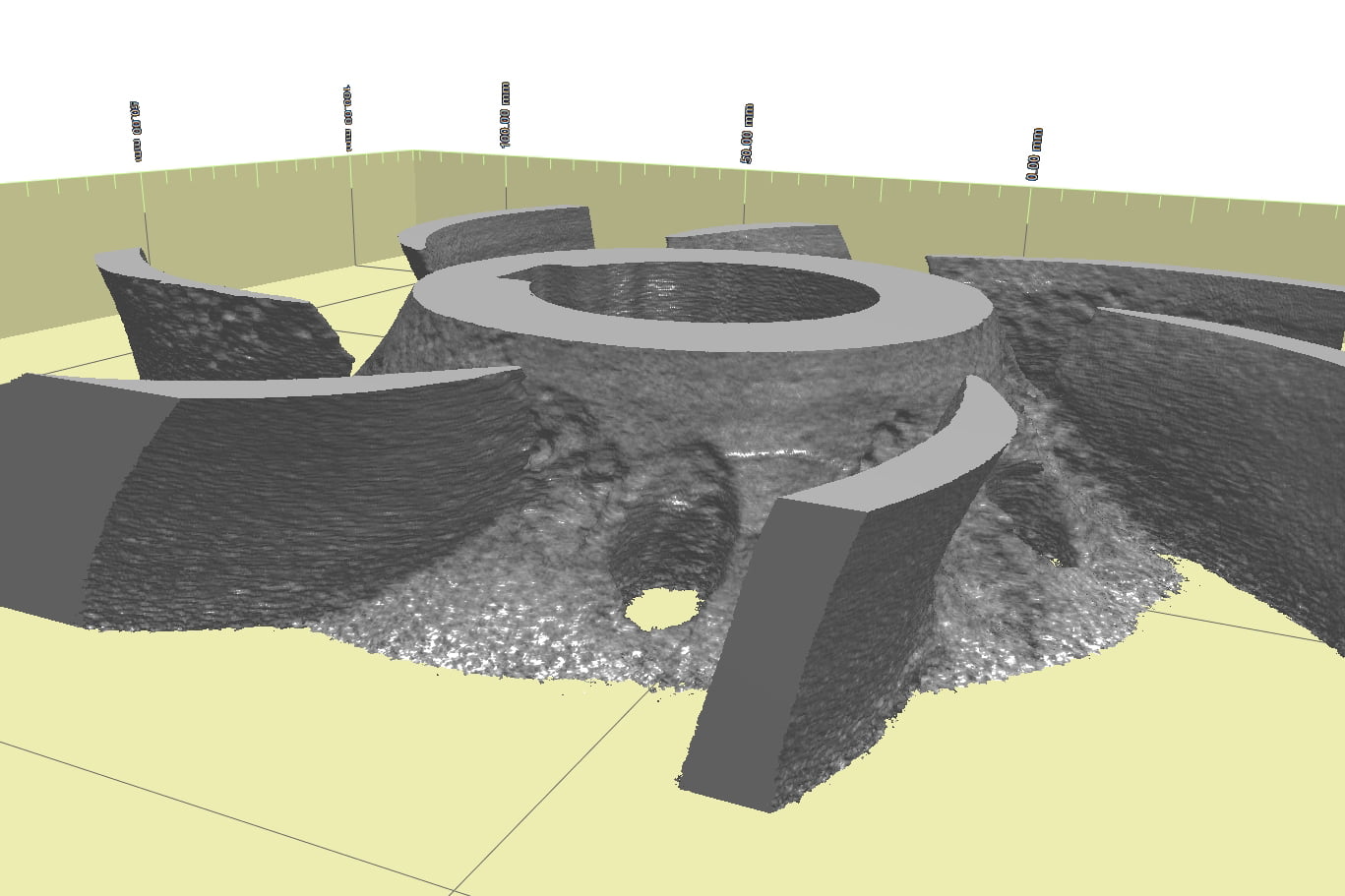

CT showing cavitation damage on metallic impeller blades

Meet the µ-VIS CT testing experts

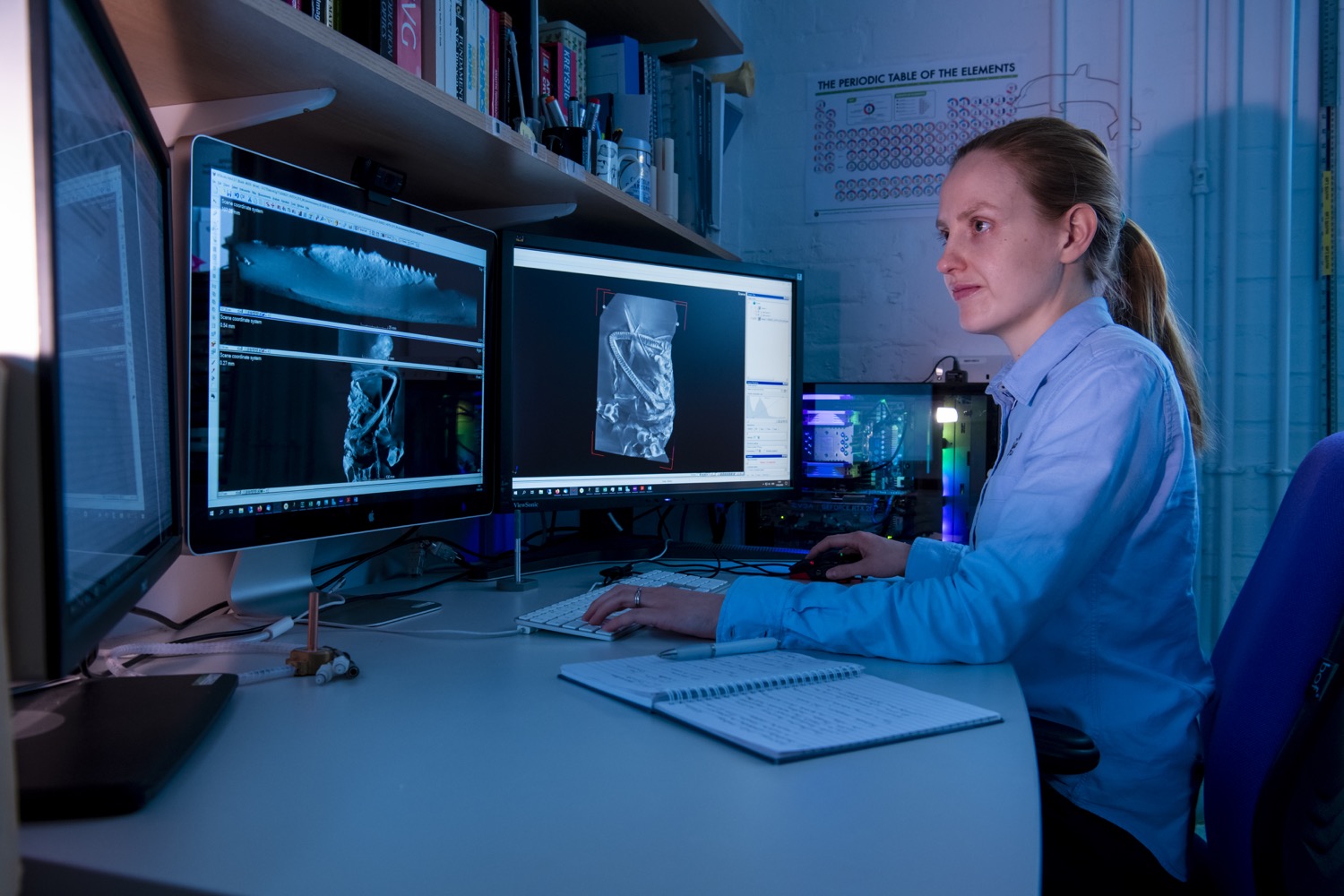

The µ-VIS X-Ray Imaging Centre specialises in bespoke consultancy services for computed tomography, associated image processing and analysis. We regularly consult CT specialists Dr Mark Mavrogordato, Dr Kathryn Rankin and the rest of the µ-VIS team, drawing on their expertise to help us provide a complete solution to your problem, however complex. With over 20 years’ experience, they offer the ability to select, configure, advise and regularly customise the CT system and image analysis methods. Find out more about Kathryn.

Dr Kathryn Rankin, µ-VIS X-Ray Imaging Centre

Professor Nicola Symonds, Director of nC2, will build a package of work that includes the scanning of your item by Mark or Kathryn, and interpretation of the data to pinpoint issues of interest. Nicola has extensive experience of identifying failure mechanisms and other tribological features through CT – from circuit board faults to the cause of an aircraft landing gear failure. She will bring this vast expertise to the resolution of your engineering issue. Find out more about Nicola.

Professor Nicola Symonds

What we offer

- Free initial consultation and bespoke quote, which may include free practice tests to determine the best test plan – if you’re not sure exactly what you need, we can advise you.

- A choice of packages to suit your requirements.

- Tests tailored to your needs, run by specialist staff in state-of-the-art labs.

- A comprehensive report including results and expert advice, plus a meeting to discuss the results.

Why choose nC2?

- An investigation, testing and analysis service of the highest quality.

- Access to specialised facilities and knowledge across the University of Southampton.

- Packages to suit your budget and requirements – whether you’re looking for a one-off test or support for a major project.

- Excellent customer service – we’ll keep you in the loop every step of the way.

- High levels of customer satisfaction.