Introduction

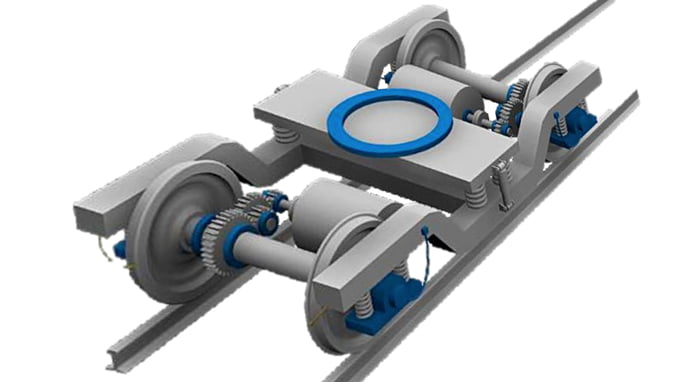

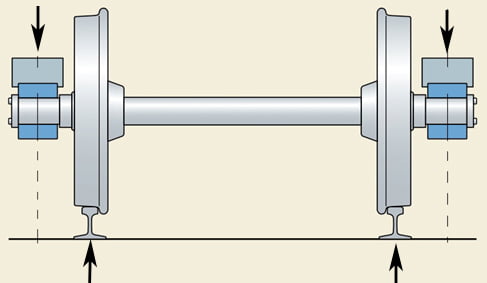

In the recent years train axle failures have caused incidents with major loss of life. The aim of this project is to research the feasibility of detecting axle cracks on trains using on-board self-powered monitoring. The vision is to use continuous live monitoring of axles with low cost self-powered wireless systems, that are easy to install, to replace expensive and disruptive NDT methods in maintenance sheds.

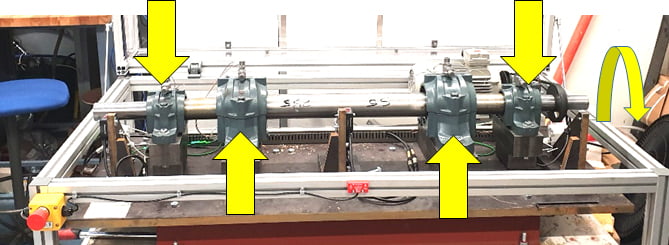

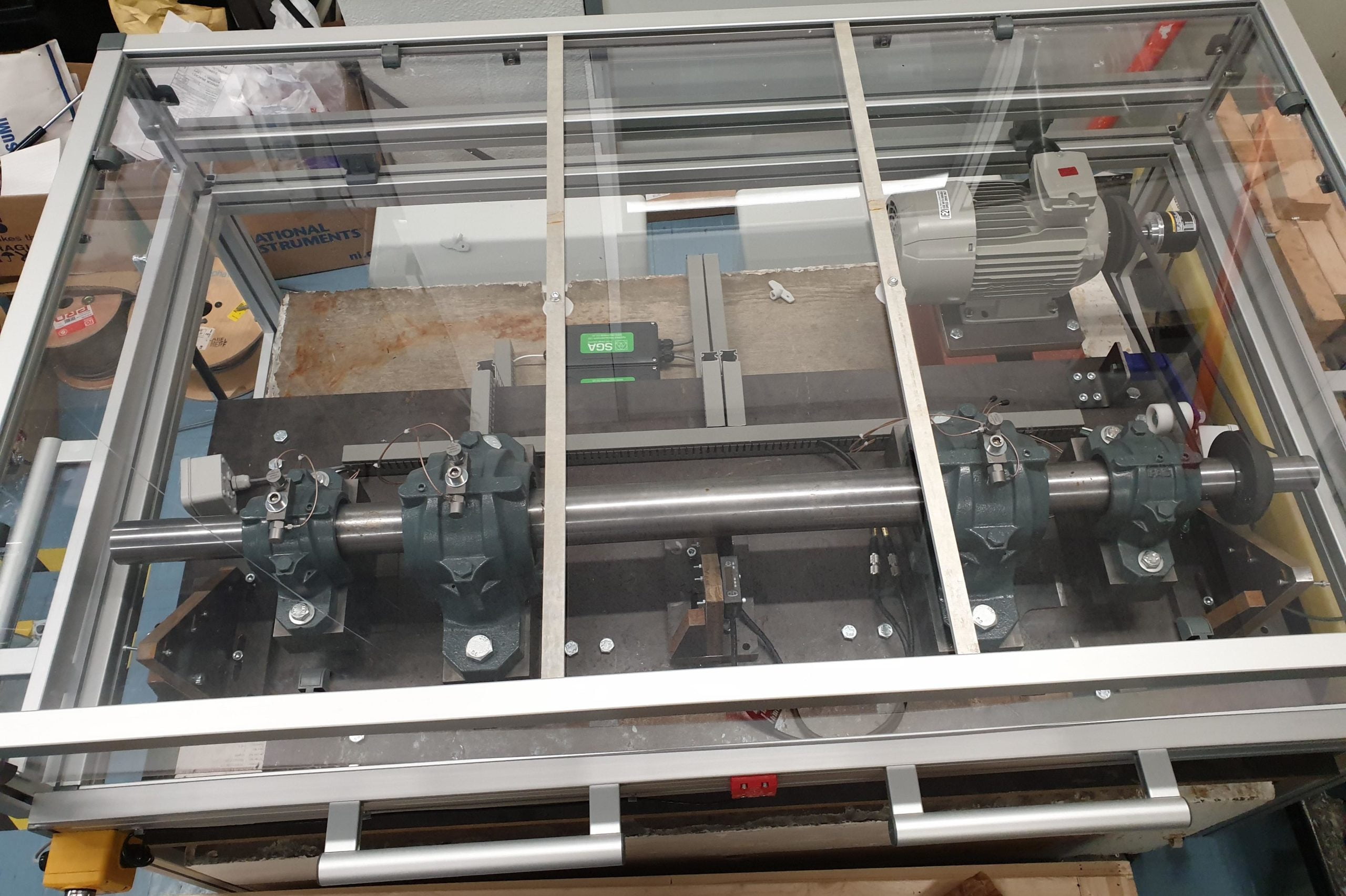

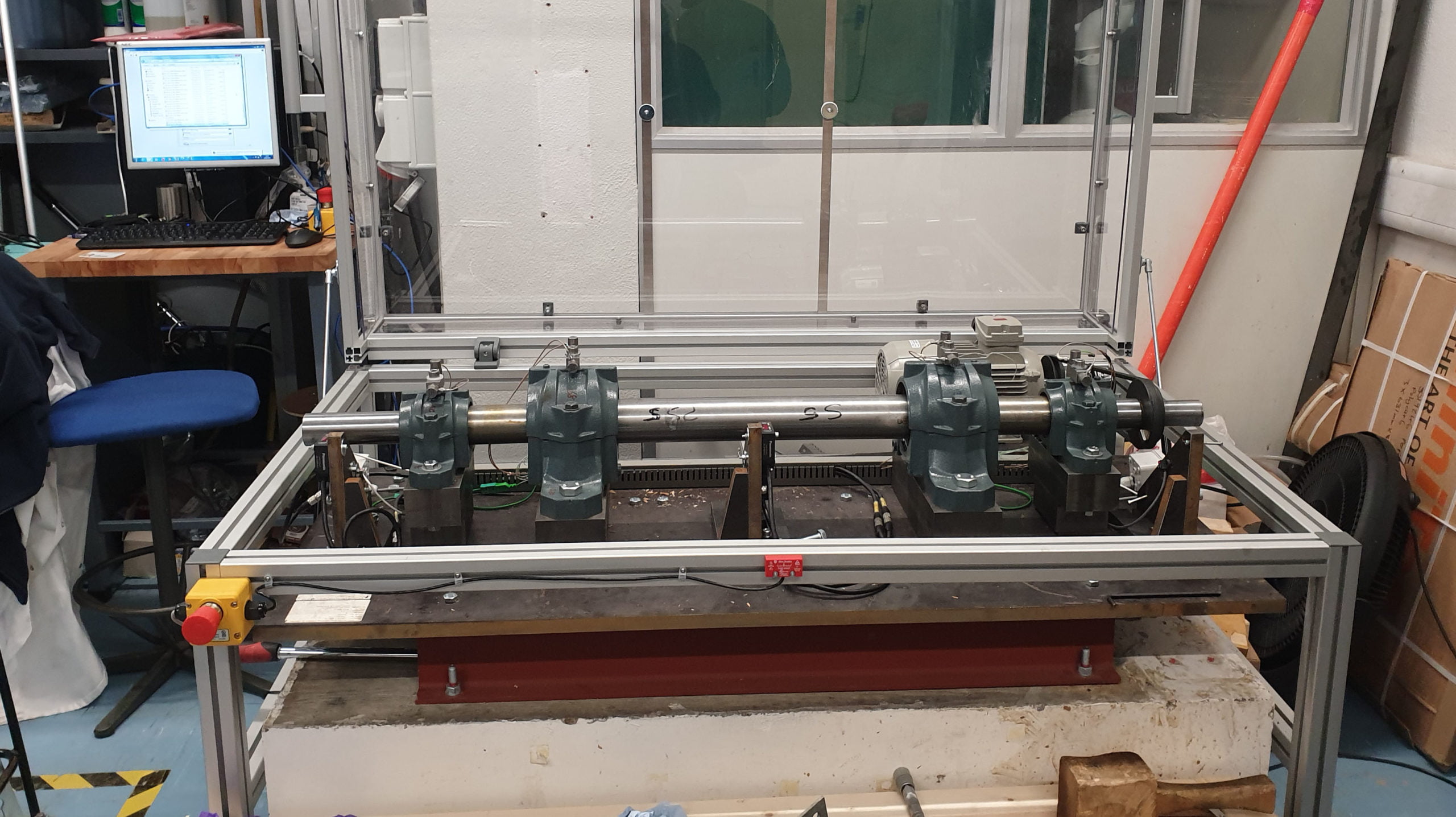

Monaxle rig

The MONAXLE rig

We designed and built this bespoke rig with the objective of exploring the use of accelerometers to detect the natural frequency of axles and to monitor how this changes in the presence of cracks. We equipped the rig with the instrumentation required to detect crack growth and to apply load to simulate the condition of a real train.

Monaxle rig side view

The objective of this new technology is to enable axle inspection regimes to extend to major overhauls only; while currently axle inspections are required on every axle, every year, taking about 24 man-hours per a 4 car unit. This is expensive and disruptive to operations. This innovative technology will provide significant cost reductions for train operators and a greater certainty on safety.

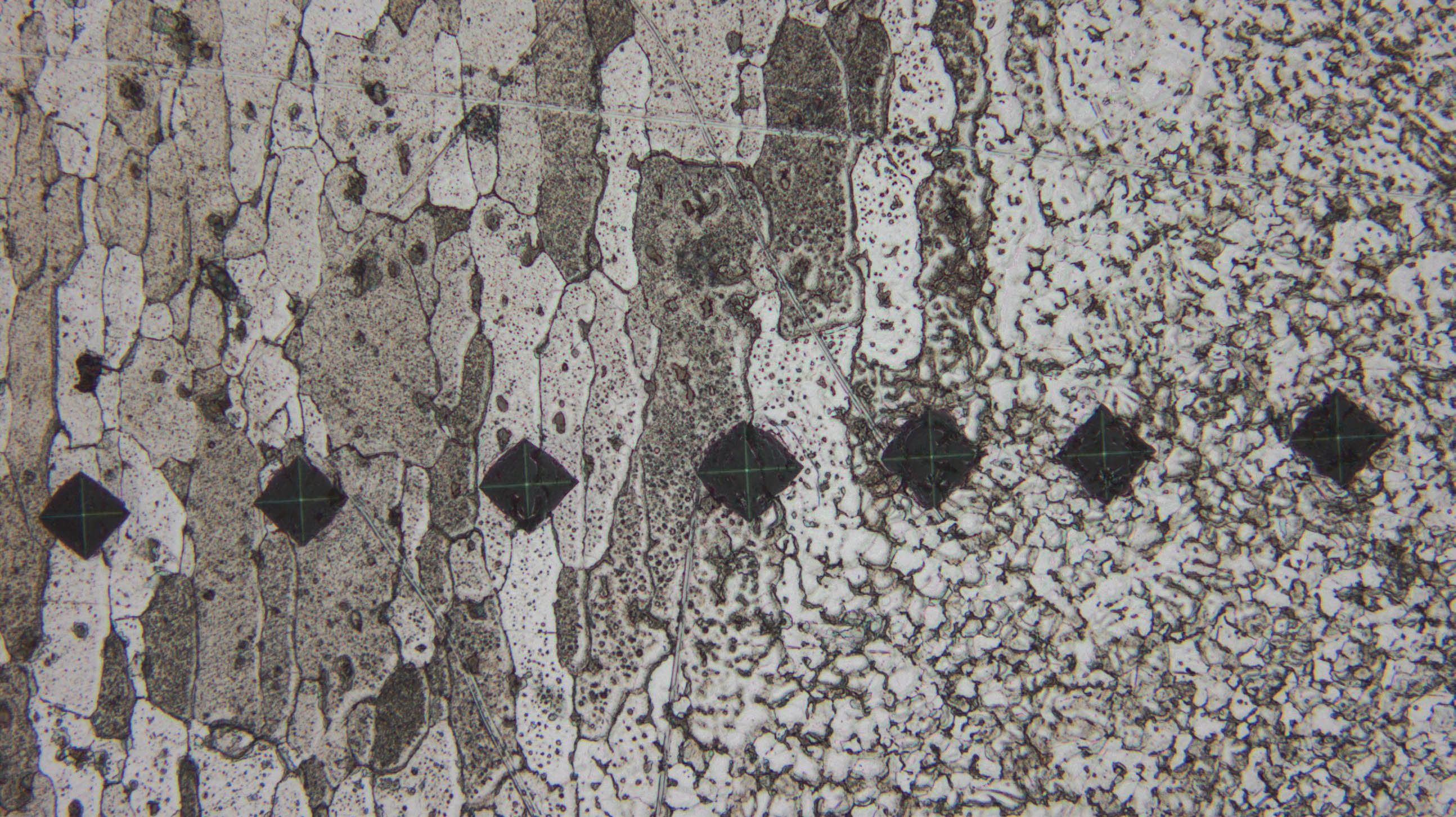

The project developed advanced low power sensing, signal processing and analytics using Perpetuum’s energy harvester powered sensor platform, a test rig built at the University of Southampton and key expertise of TWI Ltd. in non-destructive testing (NDT) and fatigue cracks propagation.

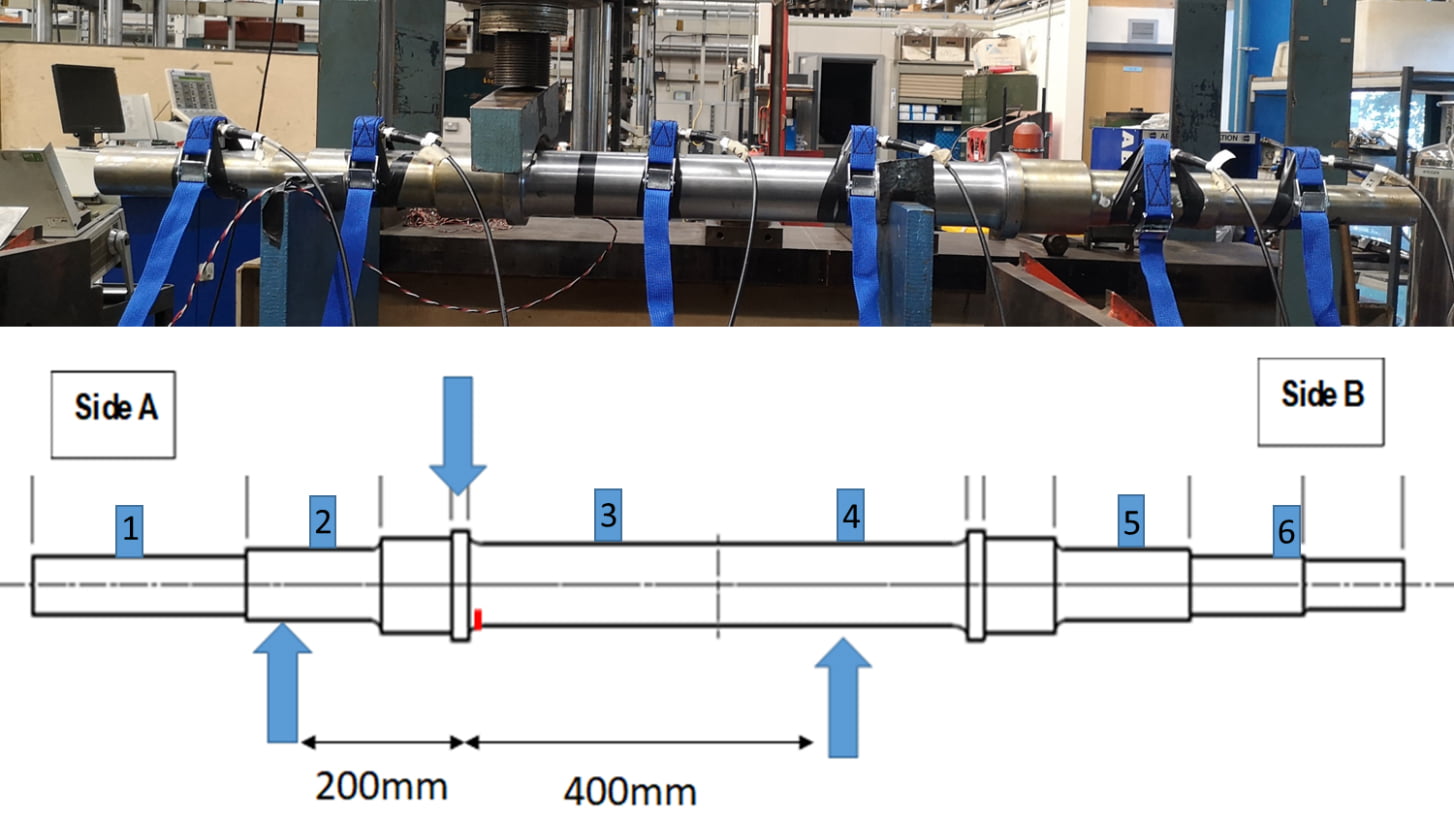

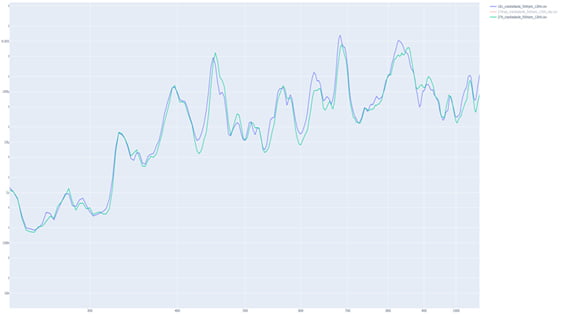

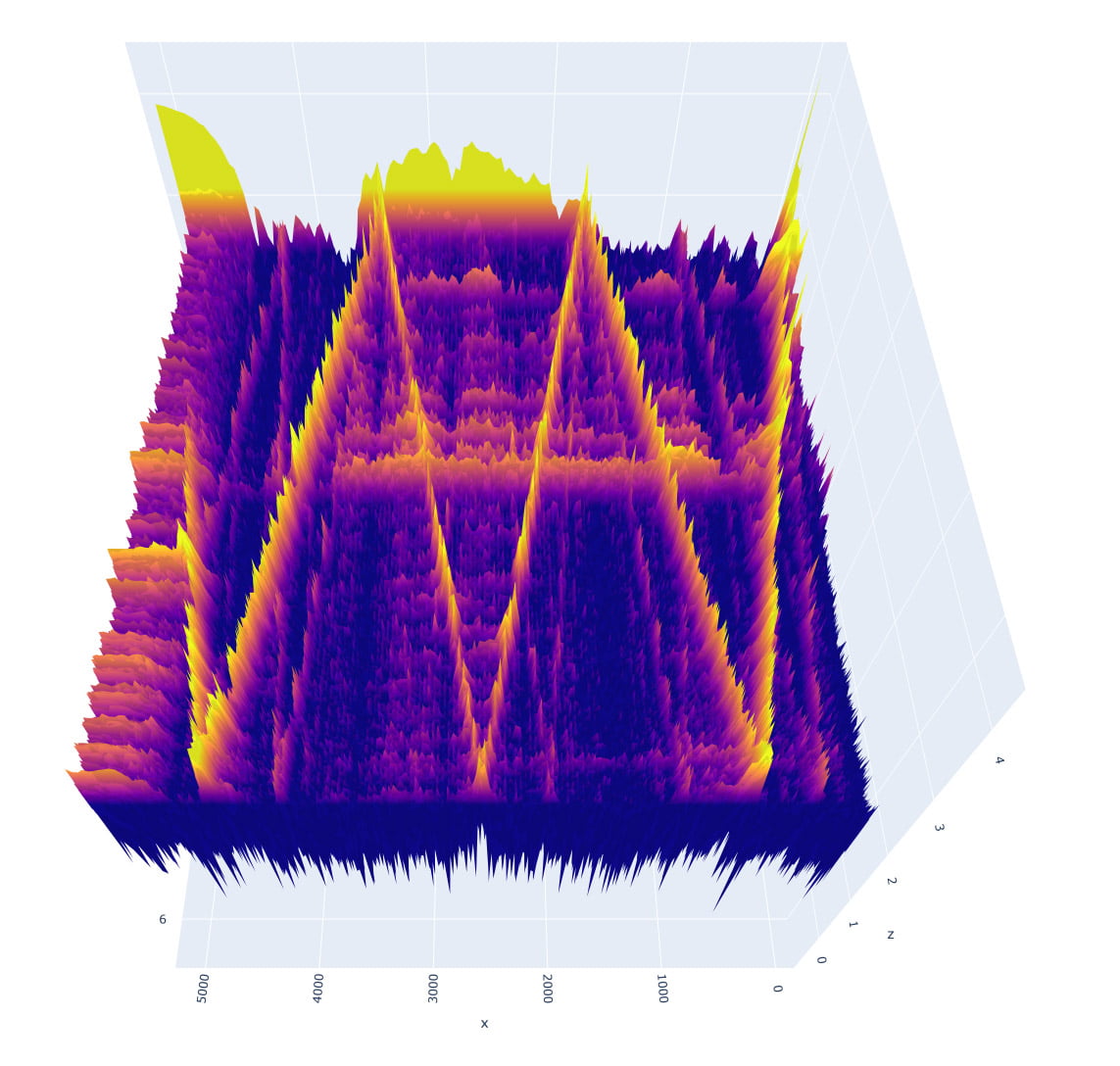

Data collected for a cracked axle

Results

We made progress in developing a sensor platform able to withstand a demanding rail freight vibration environment.

We carried out numerous tests on several scaled axles with and without cracks. The cracks were in different positions (e.g. middle of the axle or closer to the wheel) and presented different sizes (depth and length). The vibration data clearly showed that this new technology can detect the presence of cracks while the train is running. This image shows a phasogram of single axis accelerometer data collected for a cracked axle. The results will be presented at the 5th International conference of Railway Technology – RAILWAY 2021.