Professor Nicola Symonds, Director and Professorial Consultant, has led nC2 since its inception in 2015, developing it into a thriving consultancy with a highly respected team. She is known internationally for her expertise in the field of failure investigation and has extensive experience of testing and analysis across a range of industries and tribological specialisms.

Nicola graduated from the University of Southampton in 1996 with a degree in aeronautics and astronautics, staying on to complete a PhD in tribology.

She is a member of the Royal Aeronautical Society, one of the UK’s few female Chartered Engineers, and was promoted by the University Council to Professor level in 2022. In 2023 the Women’s Engineering Society (WES) named her one of the Top 50 Women in Engineering in the UK, and in 2024 she was honoured with a WES Fellowship recognising her contribution to the field of engineering and her sustained encouragement of women in STEM.

Professor Nicola Symonds

What does your role entail?

A bit of everything! As well as working in the lab on client projects, as Director my role is to take nC2 forward, and, with the team, set our strategic goals and how we’re going to achieve them. I liaise with the University, lead the team and ensure we are constantly moving ahead in terms of the quality and range of services we offer and reaching new customers.

I’m also directly involved in looking after our clients, from initial contact to the final report. When a client first gets in touch I’ll talk with them to understand what they need and how we can help. For complex multi-task jobs, I’ll take the lead on bringing our experts together to find the right solutions. I also read and sign off every report that goes to our clients, making sure our results and analysis continue to be of the highest quality.

What do you enjoy most about your work?

Failure investigation is my passion. My expertise helps agencies to understand and learn from accidents and hopefully prevent them from happening again. That’s a source of great personal satisfaction for me – being able to use my skills for good.

Alongside this, I enjoy having the autonomy to build the team and develop our offering.

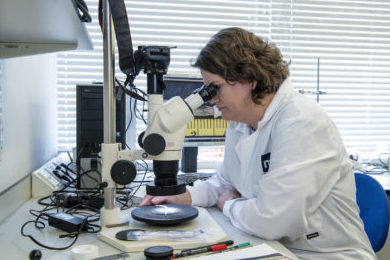

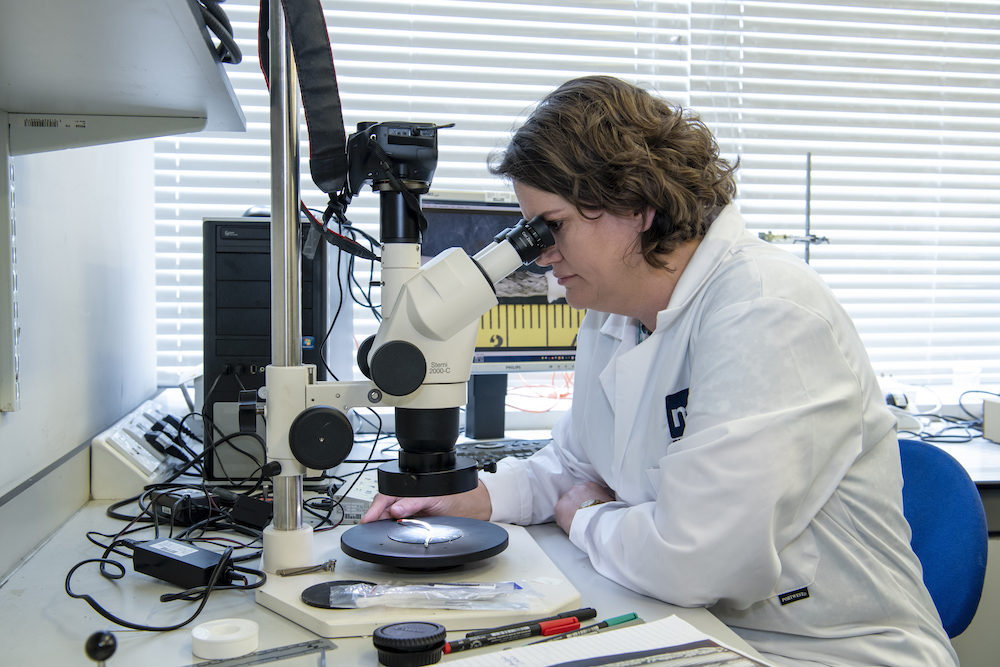

Professor Nicola Symonds examining failed components

How did you gain your specialist failure investigation skills?

I spent 10 years with the Ministry of Defence (MOD) as a forensic materials engineer, focusing entirely on investigating military incidents and accidents. During this time I worked on hundreds of incidents across the Army, Royal Air Force and Royal Navy. These primarily involved helicopters, as well as fixed-wing aircraft and hot air balloons.

I built up a breadth of knowledge that continues to grow as nC2 has taken on more investigation work. We’ve worked with the UK’s Air Accidents Investigation Branch (AAIB), Marine Accident Investigation Branch (MAIB) and Rail Accident Investigation Branch (RAIB) to help them determine the causes of failures and accidents.

What inspired you to go into engineering?

As a child I loved Star Trek and everything to do with space. Later, when I was doing A levels and trying to decide on a career, a visit to an air show made me think about studying aerospace engineering.

During my undergraduate degree I found my interest lay in the materials side of aeronautics, because it was more hands-on. So I stayed on at Southampton to do a PhD in materials science, studying the effect of wear and impact on polymeric coatings used in the oil industry.

What makes nC2’s services distinctive?

We have analytical equipment and expertise that typical test houses don’t have. This means we can look at and measure things to a very high level of accuracy and provide a lot more interpretation. We can give clients an understanding not just of how a material behaves in particular conditions, but why.

For example, most commercial test houses have equipment that can test for wear on a surface and gives the client a figure that shows how much of the material was lost. We can do the same test, but we can also use our state-of-the-art profilometry and microscopy equipment to explain why the wear is occurring, helping the client to improve their product.

In addition, we have a pool of experts in different areas of materials science that we can draw on depending on clients’ needs.

What does the future hold for nC2?

We’re growing, both in terms of the size of the team and our portfolio of services. For example, we’re introducing additional materials characterisation techniques and a new cryogenics service, tapping into more of the University’s expertise and facilities.

We look forward to continuing our partnerships with existing clients as well as working with new ones. The majority of our work is with returning clients, which speaks volumes about the quality of service we offer.