Moving parts in contact create friction. Understanding and quantifying this force can be essential if you’re designing a new product or trying to solve an engineering problem – whether you’re looking for low friction to reduce energy loss, or high friction to create additional grip or torque.

Our friction testing and analysis service will give you insights into how a pair of materials will behave when in use under different load and temperature conditions, enabling you to rank their performance. Depending on your project, you may also be interested in our abrasion testing or particulate erosion testing services.

Our friction measurement service

The nC2 team includes highly skilled specialists in tribology (the science of friction and wear). They will work with you to design tests that recreate the motion and loading conditions of your materials.

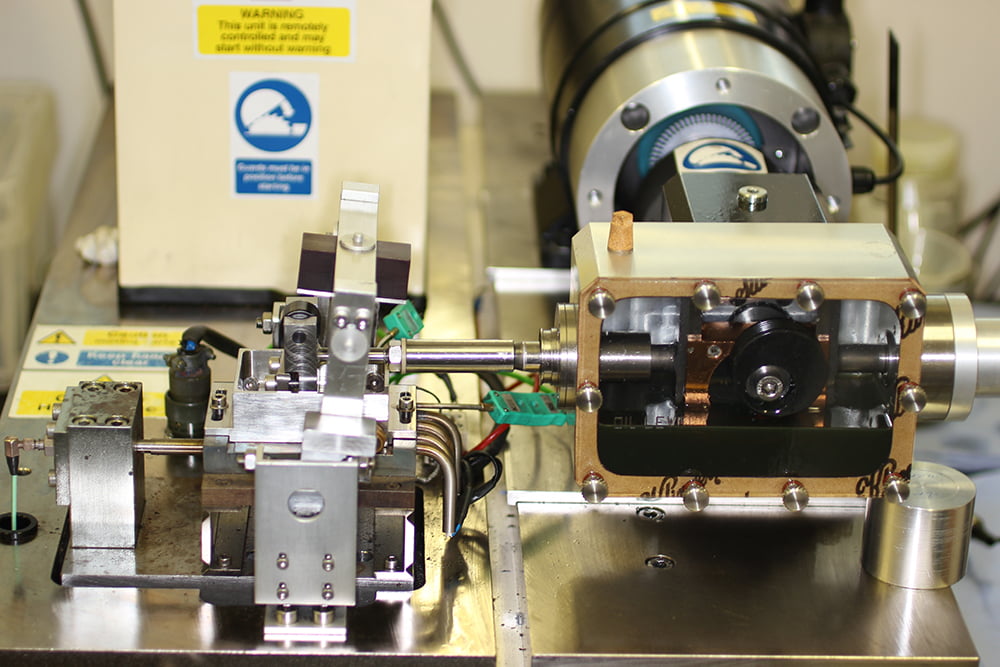

The workhorse of the nC2 tribology lab is the TE77, a reciprocating tribometer capable of high-frequency data collection. This system allows us to monitor the coefficient of friction during testing. We also have two pin-on-disc rigs that measure single direction circular track contact.

The loading and speed are computer controlled, so complex profiles can be completed quickly, continually monitoring the impact of the changes on the friction of the pair of materials.

Watch this short video to find out more about how we measure friction.

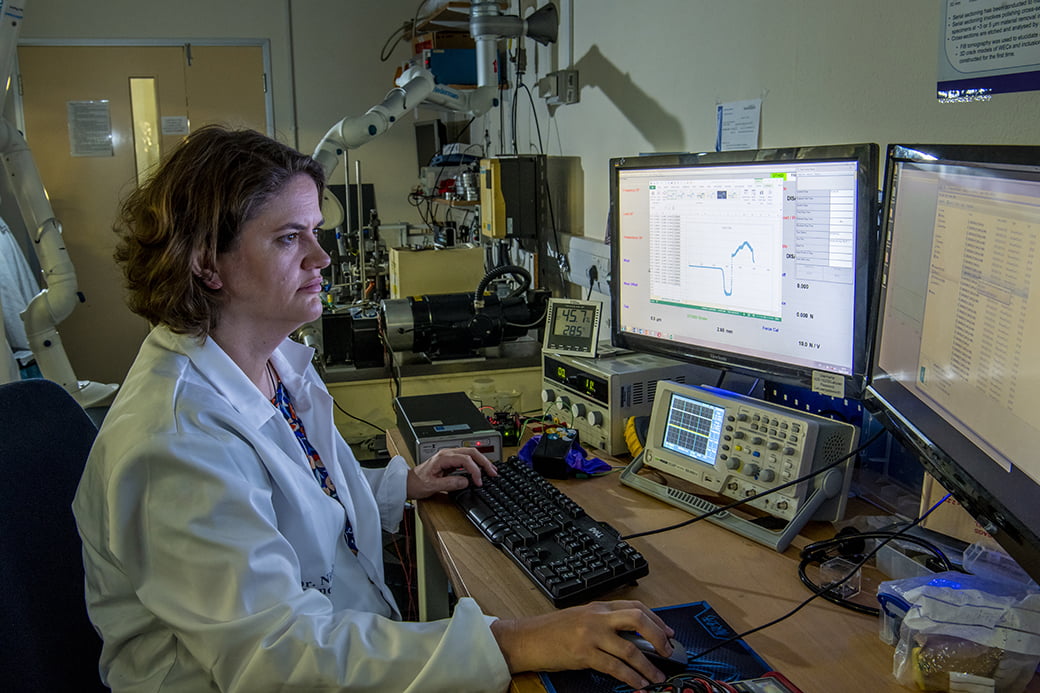

TE77 computerised control

Computer-controlled friction testing

We can use our state-of-the-art tribometers, to create different conditions for the material pair to determine:

- the absolute friction force

- the dynamic coefficient of friction (D.Cof)

- the static coefficient of friction (S.Cof)

- the sound/noise levels

Controllable parameters:

- point, line or area contact

- reciprocating or rotating motions

- relative speed: up to 14 m/s

- sliding distance

- loading fixed or variable: up to 1000 N

- lubricated or dry

- submerged in a bath or dripped lubricant

- room temperature, chilled or heated: up to 600°C

- pin material and finish

- plate material and finish

The TE77 reciprocating tribometer

Meet our friction measurement experts

Professor Nicola Symonds, Director of nC2, takes the lead on our friction testing services. With a doctorate in tribology and extensive experience of friction testing projects, she has the expertise to identify the optimum test conditions for your materials and provide in-depth analysis of the results. Find out more about Nicola.

Professor Nicola Symonds

We also receive expert support from Dr Terry Harvey, Senior Research Fellow and Facility Manager for the national Centre for Advanced Tribology at Southampton (nCATS). Terry has 25 years’ experience in the field of tribological testing, including industry consultancy, and knows the nCATS’ tribometers inside out. He advises us on test design and programmes the equipment, helping us to ensure our clients get the outputs they need. Find out more about Terry.

Dr Terry Harvey

What we offer

- Free initial consultation and bespoke quote, which may include free practice tests to determine the best test plan – if you’re not sure exactly what you need, we can advise you.

- A choice of packages to suit your requirements.

- Tests tailored to your needs, run by specialist staff in our state-of-the-art labs.

- A comprehensive report including results and expert advice, plus a meeting to discuss the results.

Why choose nC2?

- A testing service of the highest quality, plus expert analysis of the results.

- Access to highly specialised facilities and knowledge across the University of Southampton.

- Packages to suit your budget and requirements – whether you’re looking for a one-off test or support for a major project.

- Excellent customer service – we’ll keep you in the loop every step of the way.

- High levels of customer satisfaction.