The materials used in the structure of tanks and military platforms are coated, in part to protect them from corrosion. However, some coatings contain corrosion-inhibiting chemicals that are harmful to human and environmental health and no longer comply with REACH legislation (Registration, Evaluation, Authorisation and restriction of Chemicals).

nC²’s corrosion experts have been working with DSTL to find alternative products that are free from substances of very high concern (SVHCs), by evaluating samples which have undergone accelerated corrosion tests to ISO/commercial standards.

The project involved three phases:

Phase 1: We tested seven paint schemes using accelerated corrosion tests and outdoor exposure tests to identify the best performers.

Phase 2: We used accelerated test regimes to test the best performing primer and coating, with additional testing to see the effects of UV, pull-off adhesion and scratch resistance.

Phase 3: The results of Phases 1 and 2 were used to identify which of the accelerated tests were most comparable to the long-term outdoor tests, which more closely replicate in-service conditions. We analysed a further four paint schemes, two used for MOD land equipment and two for marine equipment, to determine their performance. We also designed an automated process to analyse the results of cross hatch testing (a test used throughout the project which involves scraping a coated sample to see how much of the coating is lost) to improve the speed and consistency of the analysis.

The results will enable DSTL to choose the best coating for its requirements and the most robust techniques for selecting coatings in future.

Technical details about each phase are described below:

Phase 1

We analysed seven paint schemes using five accelerated corrosion tests (ISO 4623/2, GM9540P-B, D172028, ISO16701 and BS3900:F12) of three-month duration. We compared these test data to outdoor exposure tests carried out for 18 months in two static locations and one on vehicles; these were used to replicate the typical UK conditions.

Prior to testing, we assessed the mass, the gloss (at 20/60/85º geometries), the colour (L, a and b colour space) and the dry film thickness and kept visual records of the specimens. We then monitored these characteristics over the duration of the test. We also carried out cross hatch adhesion and a visual assessment of blistering of the coating or corrosion of the aluminium substrate.

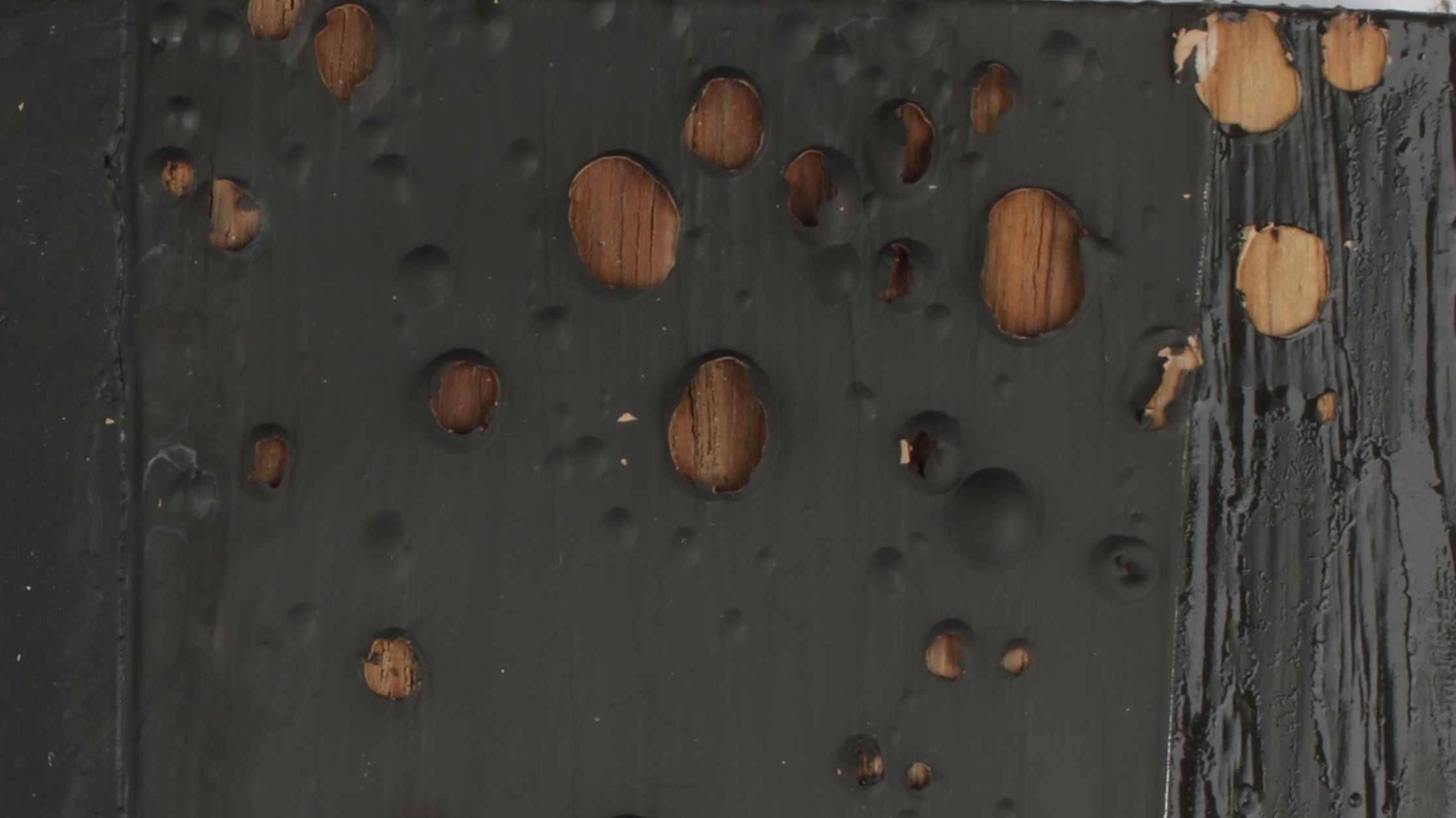

Removing samples after exposure

Samples under test

Phase 2

The Phase 1 results identified a coating and primer that outperformed the other coatings. For Phase 2, we performed two accelerated test regimes, chosen by the client, for analysis on two different substrates.

As in Phase 1, we monitored the gloss, the mass, the colour and the visual appearance over time. In addition to these characteristics, we also undertook a four-month UV analysis to BS EN ISO 16474-3 to asses the effect of sunlight/UV on the coatings. We also expanded our testing to include pull-off adhesion to BS EN ISO 4624 and scratch resistance to BS EN ISO 1518-1.

In addition to the standard analysis we carried out in Phase 1 we also carried out tests to determine the performance of the coatings in oil liquid fuel and water.

Phase 3

Phase 3 of the project started in 2021 with the aim of deciding on the most representative test techniques that were developed during the first two phases. In addition we analysed a further four paint schemes, two used on MOD land equipment and two for marine equipment, to determine their performance.

During Phase 1 and 2 we identified that the cyclic tests, in particular the ISO 16701, replicated the corrosion mechanisms observed in the long-term testing to a better extent than neutral salt spray tests such as BS 3900 F12.

The cyclic tests, however, are not as aggressive as the continuous salt spray tests and have longer testing periods. In this phase, therefore, we looked into changing some of the parameters of the standard such as salt concentration and temperature, as well as to include UV cycle to accelerate the testing.

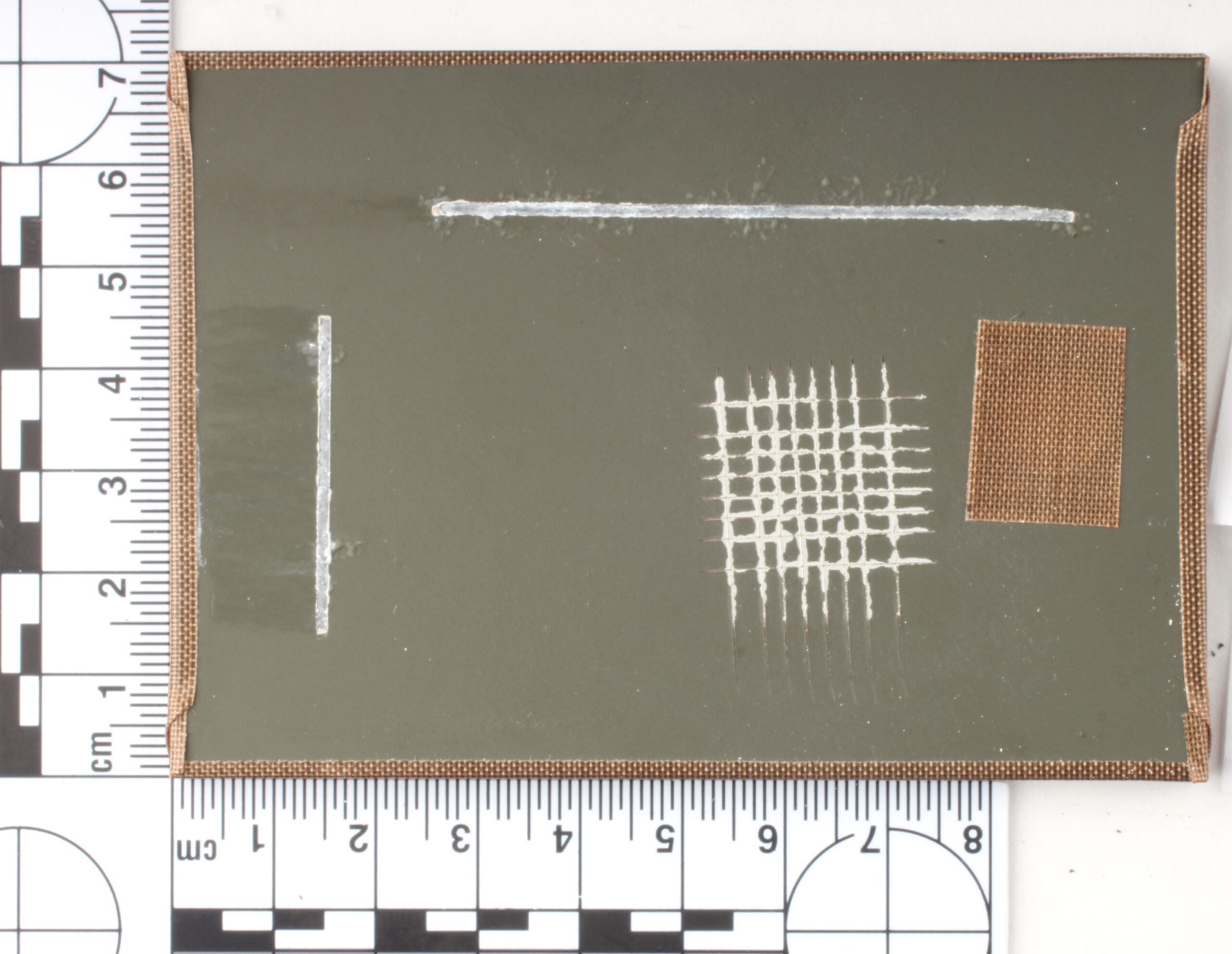

Phase 3 samples under test

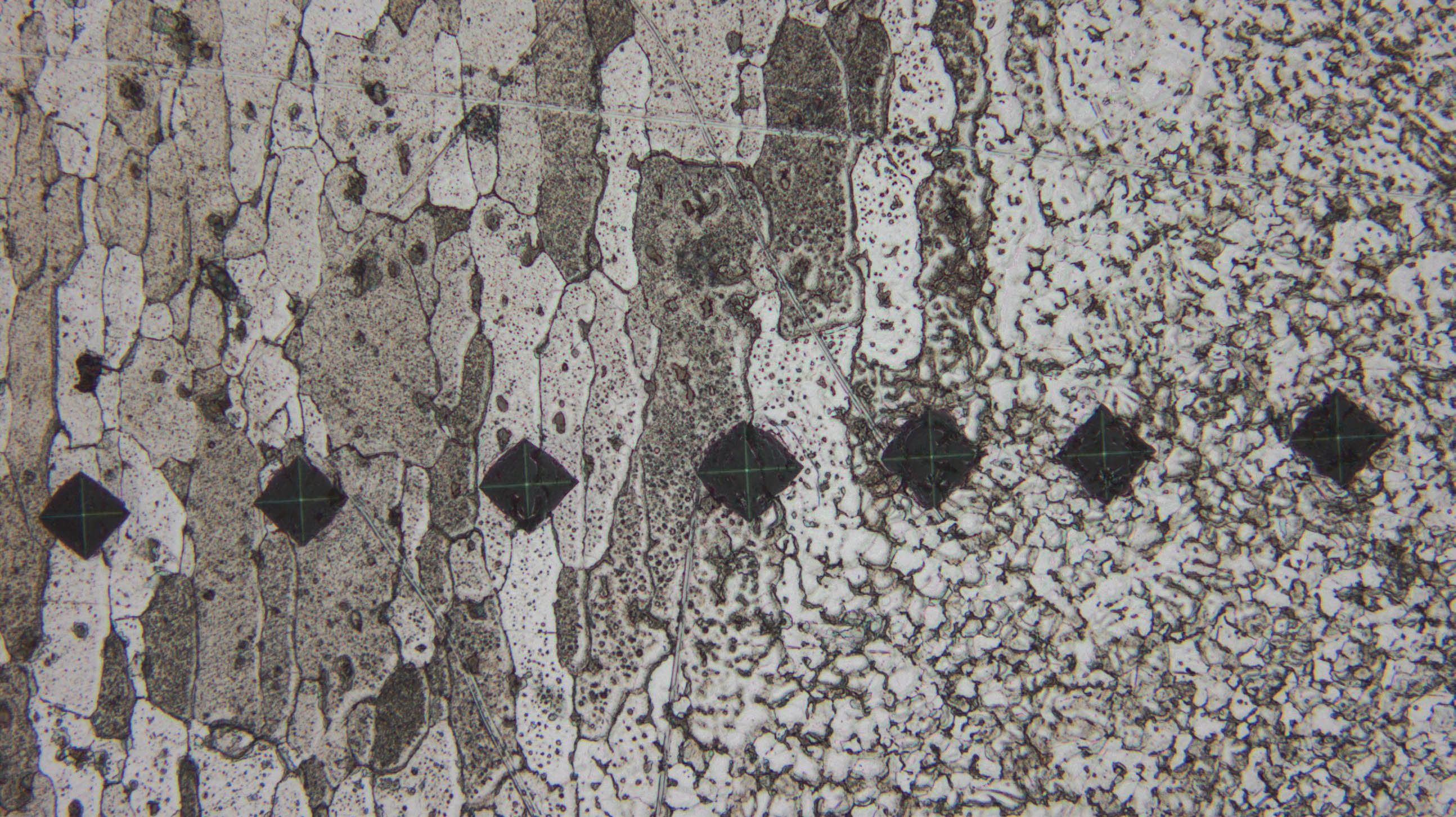

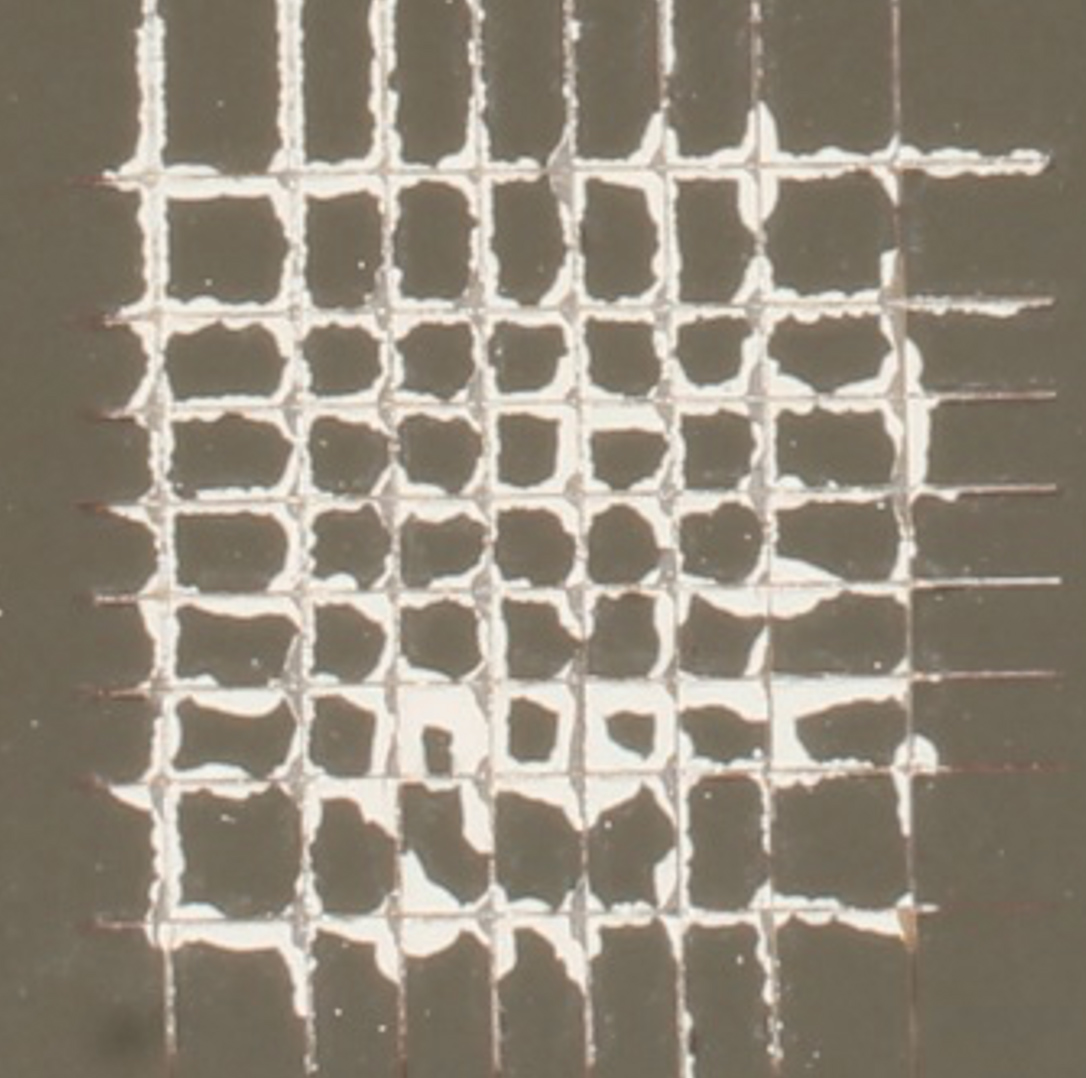

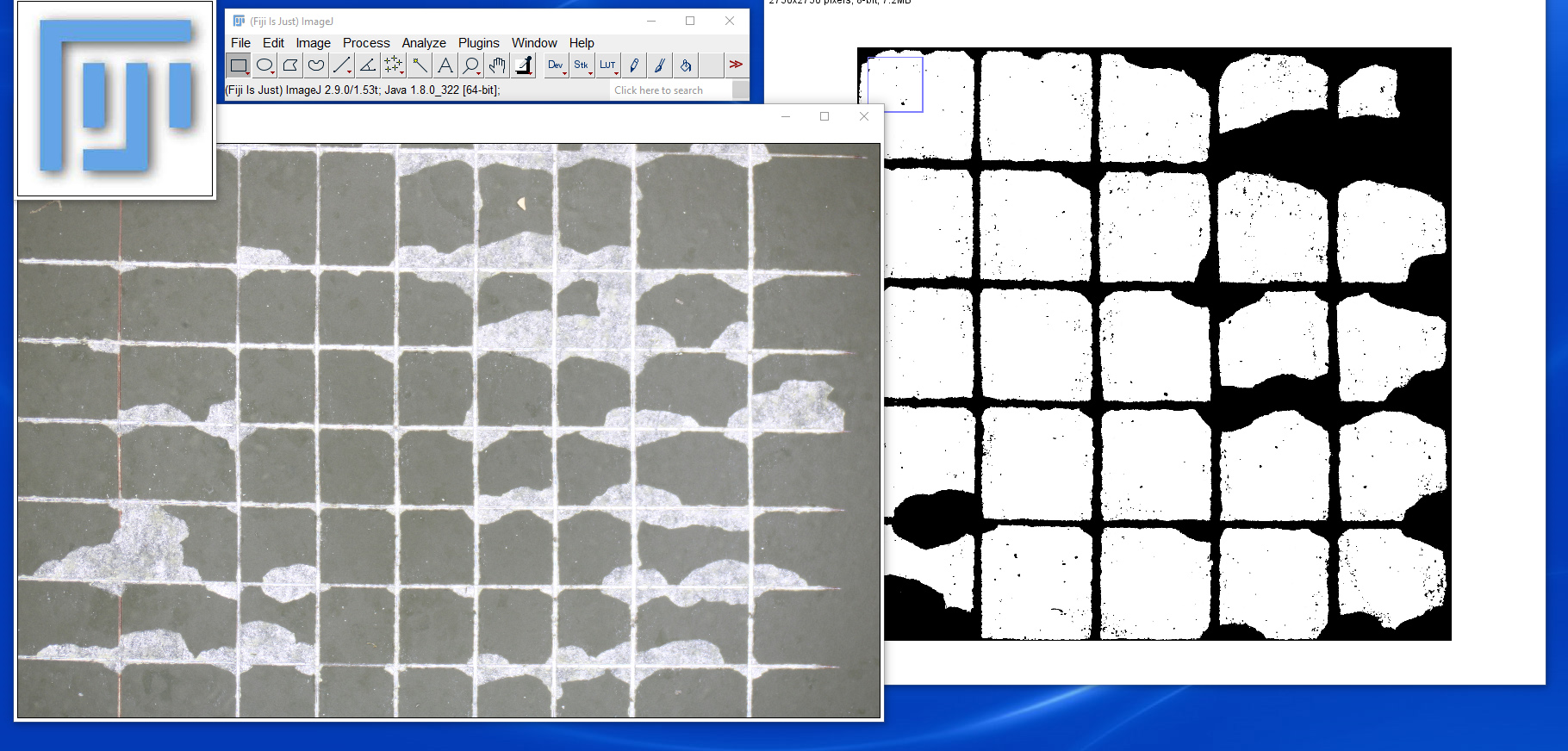

A further aim of this phase of the testing was to automate the cross hatch testing that has been used extensively during the project to assess coating adhesion. The analysis of the cross hatch involves estimating the amount of paint lost when a right-angle lattice pattern is cut into the coating. The pattern created is compared to a table in the standard and the coating given a rating.

However, some inconsistencies in the operators’ assessment of the samples were noted during the testing. To address this we developed a digital technique within ImageJ/FIJI, which is universally available, to enable the percentage of coating loss to be categorised quickly and accurately for each image

.