Metals naturally degrade when they are exposed to the elements – understanding how and at what rate is crucial for new product design.

We have the expertise and cutting-edge facilities to give you insights into how metals behave in specific conditions, from electrochemical measurements to undersea immersion.

The results will enable you to choose the most effective corrosion-resistant solution for your product, whether you’re working with carbon steel, stainless steel, aluminium or any other metal.

For coated materials we also have a full range of paint and coatings testing services.

Our corrosion testing services

We will work with you to design bespoke tests to suit your requirements, for example:

- long-term environmental tests which expose samples to specific conditions over a period of months

- shorter-running electrochemical tests, which accelerate the corrosion process

- or a combination of the two, allowing us to correlate results for additional insights

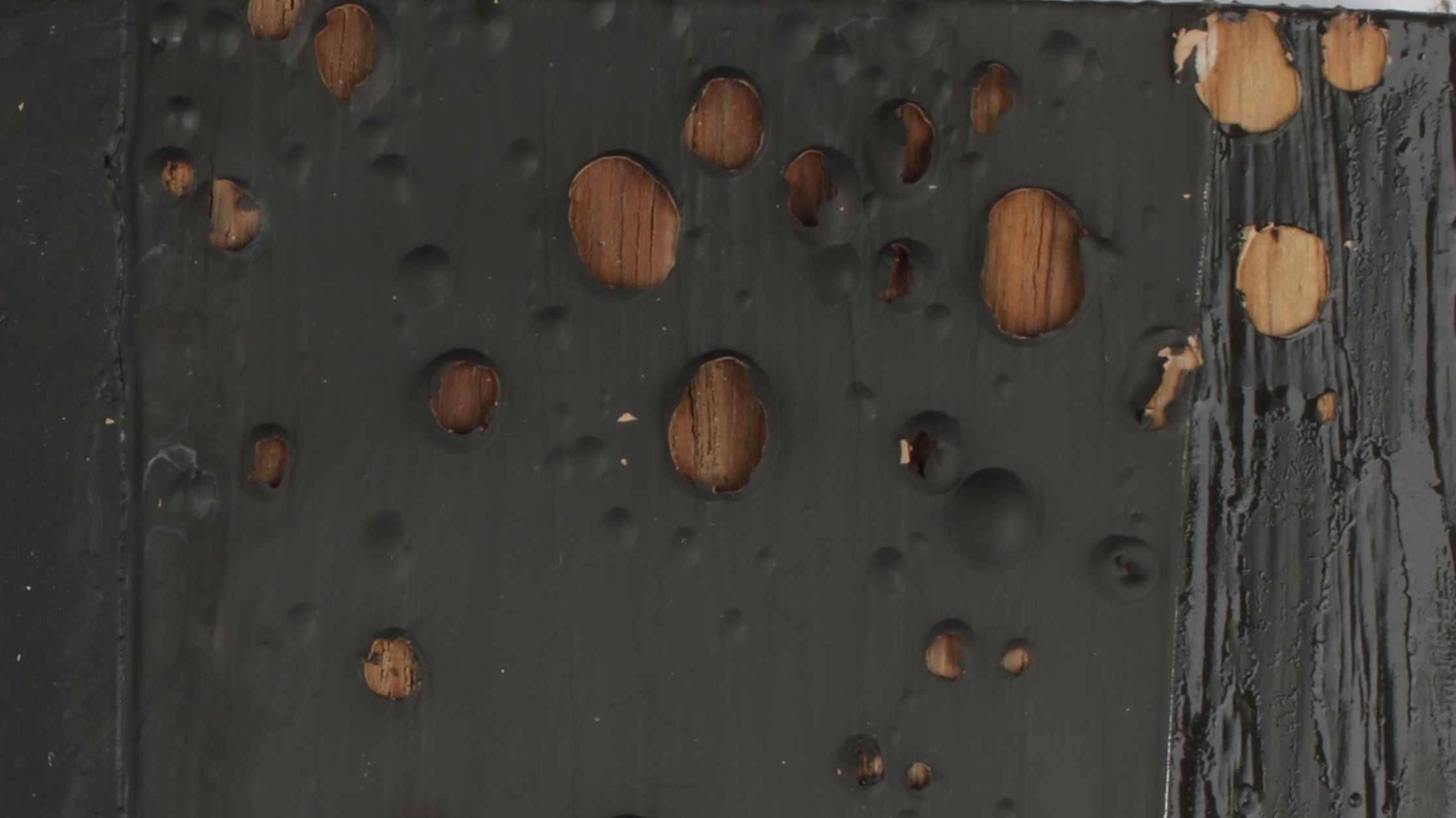

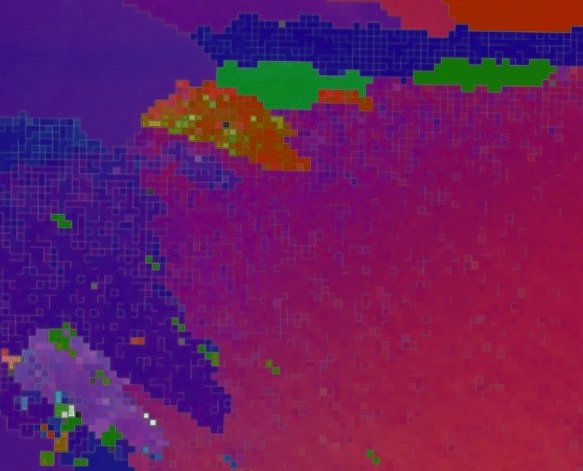

After testing, we analyse the samples using a range of state-of-the-art characterisation equipment to identify the type of corrosion affecting the materials, whether general corrosion, crevice corrosion, galvanic corrosion or stress corrosion.

Corrosion control team

Our environmental test facilities include:

- environmental chambers (salt fog, salt spray testing, humidity and temperature)

- UV cabinet

- long-term submerged sea water exposure facilities at the National Oceanography Centre Southampton

- outdoor exposure racking with weather station

- cathodic protection measurement equipment

ur electrochemical testing facilities

Our benchtop laboratory potentiostats are capable of various electrochemical techniques and corrosion testing methods to determine corrosion rates and surface characteristics. Testing services include:

- Tafel extrapolation

- linear polarisation resistance

- zero resistance ammetry

- impedance spectroscopy

- potential monitoring

Post-test analysis

- We have facilities for a full analysis of the nature and extent of corrosion, including scanning electron microscopy, CT scanning and a full range of metallurgical testing services where required. Find out more about our materials characterisation services.

- You’ll receive a comprehensive report detailing our results and analysis on the effects of corrosion, and we will be happy to discuss the findings with you.

- We can use the results to rank materials for resistance to corrosion under your specified conditions.

Electrochemical corrosion tests

Meet our corrosion testing experts

Spencer Court, Senior Corrosion Consultant, is our corrosion and environmental conditions testing specialist. Having joined nC2 in 2016 after 15 years in the oil/gas and marine industries, he has a wealth of experience and expertise to bring to your corrosion testing project. Find out more about Spencer.

Dr Spencer Court

Spencer works closely with Professor Julian Wharton, a corrosion and surface engineering expert at the national Centre for Advanced Tribology at Southampton (nCATS). Julian brings his extensive experience in the field of corrosion research and industry consultancy to our clients’ projects, advising on test packages and applying his academic rigour to the analysis and interpretation of the results. Find out more about Julian.

Professor Julian Wharton

What we offer

- Free initial consultation and bespoke quote – if you’re not sure exactly what you need, we can advise you.

- A choice of packages to suit your requirements.

- Tests tailored to your needs, run by specialist staff in our state-of-the-art labs.

- A comprehensive report including results and expert advice, plus a meeting to discuss the results.

Why choose nC2?

- A testing service of the highest quality, plus expert analysis of the results by staff with extensive industrial experience.

- Access to highly specialised facilities and knowledge across the University of Southampton.

- Packages to suit your budget and requirements – whether you’re looking for a one-off test or support for a major project.

- Excellent customer service – we’ll keep you in the loop every step of the way.