Any product with moving parts will be subject to abrasion and wear. Our bespoke testing and analysis service can give you insights into the abrasion mechanisms at play under specific conditions.

Clients seek our services for various reasons, whether it’s to find the most suitable coating for a new product, to learn whether a product will last for its intended lifespan, to set appropriate inspection and maintenance schedules, or to improve a design where abrasion has caused failure.

Abrasive wear testing team

We have the facilities to test for two-body and three-body abrasion:

- Two-body abrasive wear occurs when two materials rub together and the harder material removes matter from the softer one – like the action of sandpaper on wood.

- Three-body abrasive wear involves loose particles removing material from a surface – for example, sand or grit inside a bearing.

We’ll advise on the right tests for your needs, simulating the required environment as closely as possible in the lab and offering expert analysis of the results.

Our abrasion testing services

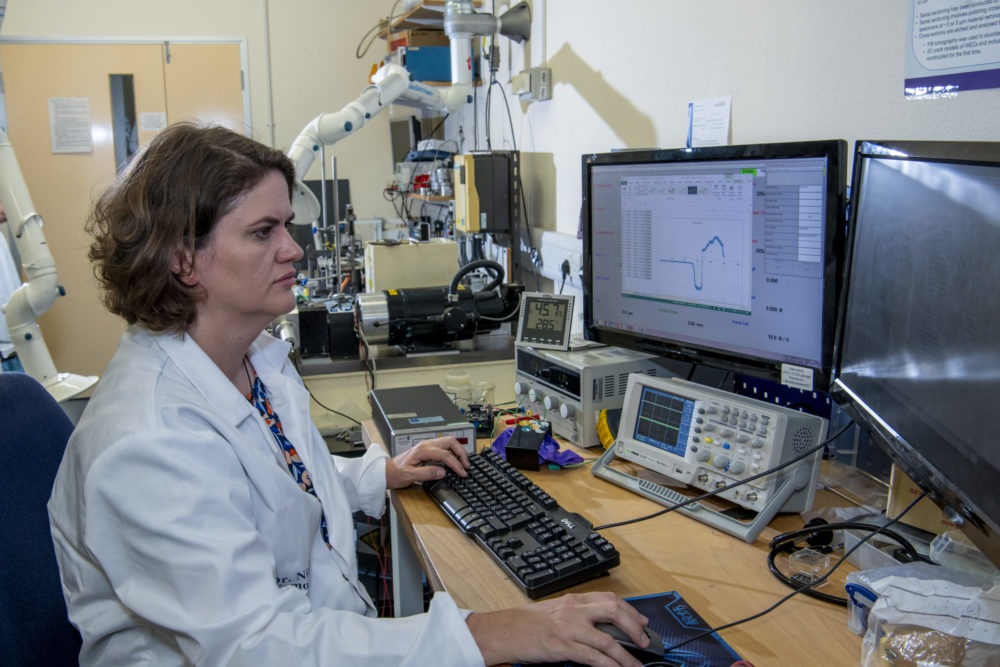

Sliding wear testing

We use the TE77, a reciprocating tribometer, to measure the volume loss of material through sliding wear. The loading and speed are computer controlled, allowing us to quickly complete complex testing profiles.

Controllable parameters include:

- type of contact (point, line or area contact)

- reciprocating (back and forth)

- range of stroke lengths and cyclic speeds

- loading to 1,000 N

- temperature, from chilled to 600°C

- lubricated or dry, and/or with added particulates

We also have two pin-on-disc rigs that measure single direction circular track contact.

With the TE77 we can quantify the friction of a pair of materials using high-frequency data collection methods. Find out more about our friction measurement service.

TE77 for sliding wear

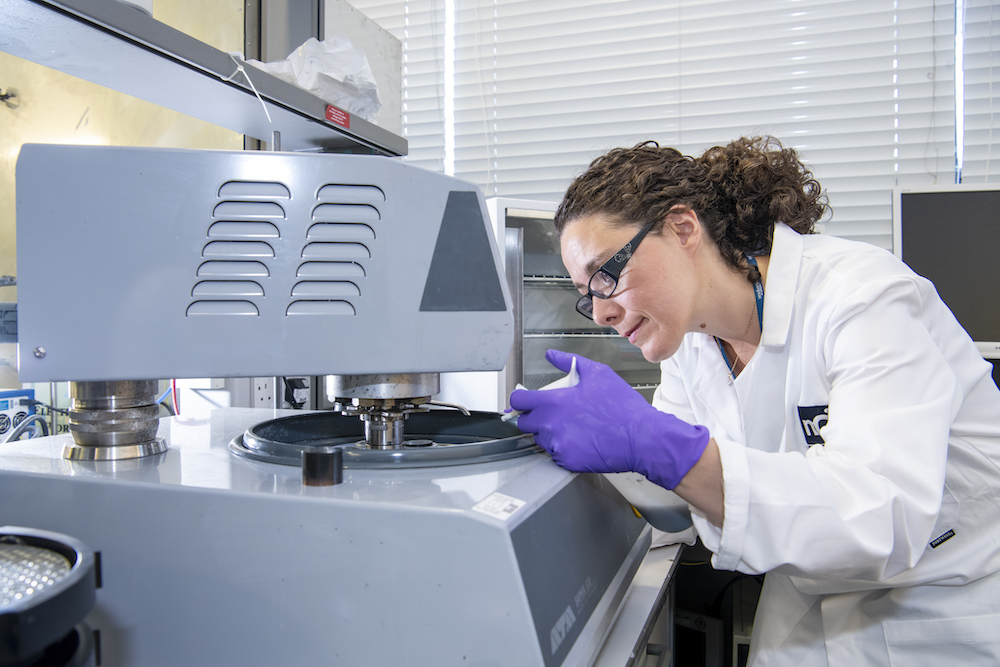

Micro abrasion

Micro-abrasion testing

For this we use a TE66 micro-scale abrasion tester. The material to be tested is loaded against a rotating ball in the presence of an abrasive slurry. This is a reliable method with a high level of test control and repeatability.

Our micro-abrasion testing complies with BS EN ISO 26424: 2016 and has many applications. We can measure the wear coefficient of monolithic materials, hard and soft coatings and accurately determine multi-coating thickness.

It’s an effective way of rapidly screening different samples in order to select the most suitable ones for more detailed tests on the TE77.

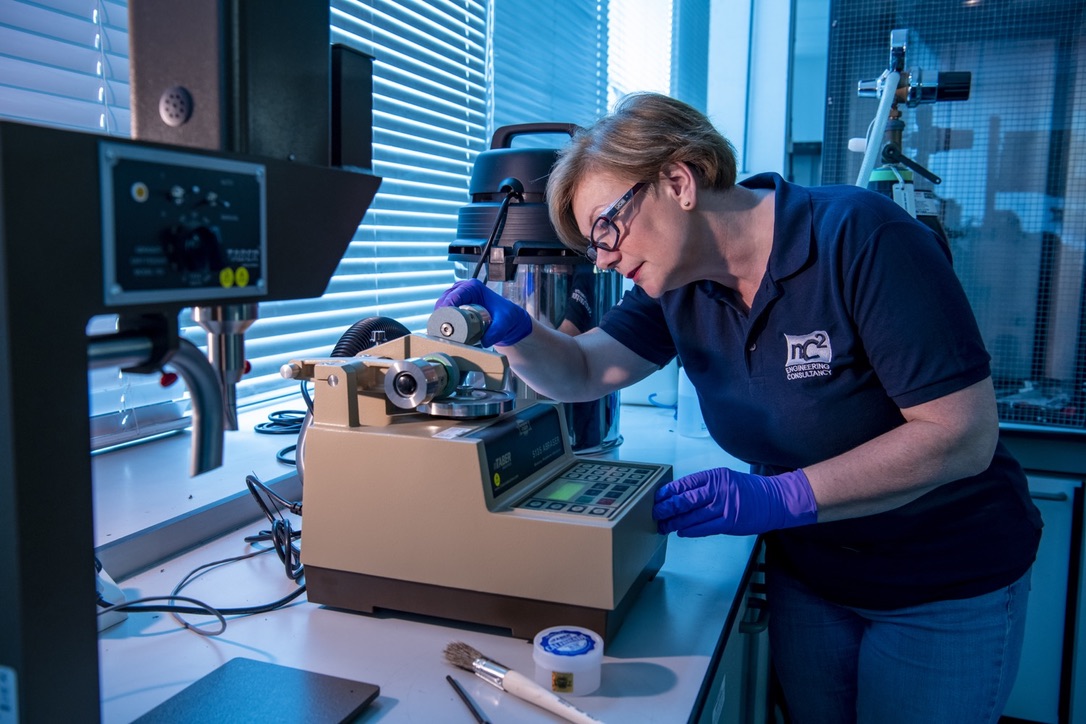

Taber Abraser wear testing

We use a genuine Taber Abraser to test the ability of a material or coating to resist abrasion. A flat specimen is mounted onto a turntable and rotated at a known fixed speed. The resulting wear tracks can be profiled or evaluated for mass loss or changes in appearance.

We can also evaluate three-body abrasion by introducing grit uniformly and continuously at a specific rate.

There are various standard test methods that are used; the most common are:

- ASTM D4060 Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser

- BS ISO 9352 Plastics – Determination of Resistance to Wear by Abrasive Wheels

The Taber Abraser can be used to test to many more standards; a full list can be found on the Taber Industries website.

Taber Abraser

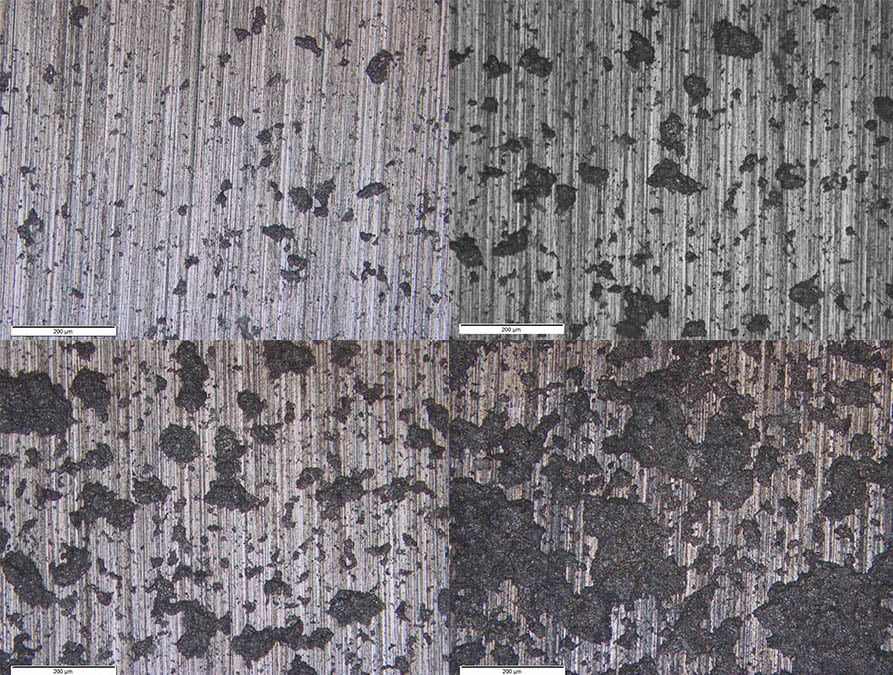

Post-test analysis

We analyse the results with our state-of-the-art imaging, microscopy and profilometry equipment. We’ll provide a detailed report and our expert opinion as required to help you decide on next steps.

Meet our abrasion testing expert

JB, Senior Consulting Engineer, is our abrasion and erosion specialist. With more than 16 years’ experience working with industry clients on tribology projects, JB is ideally placed to advise you on the best approach and design the right abrasion tests for your needs. Find out more about JB.

Dr Jelili Bello

What we offer

- Free initial consultation and bespoke quote, which may include free practice tests to determine the best test plan – if you’re not sure exactly what you need, we can advise you.

- A choice of packages to suit your requirements.

- Tests tailored to your needs, run by specialist staff in our state-of-the-art labs.

- A comprehensive report including results and expert advice, plus a meeting to discuss the results.

Why choose nC2?

- A testing and analysis service of the highest quality.

- Access to specialised facilities and knowledge across the University of Southampton.

- Packages to suit your budget and requirements – whether you’re looking for a one-off test or support for a major project.

- Excellent customer service – we’ll keep you in the loop every step of the way.

- High levels of customer satisfaction.