Rachel Triggs, Senior Consultant, joined the team in 2021 having worked on various nC2 projects as a contractor since 2016.

With a chemistry degree from the University of Southampton and 15 years’ experience working on corrosion control projects at the MOD, she brings a wealth of knowledge and expertise to her work at nC2.

What are your areas of expertise at nC2?

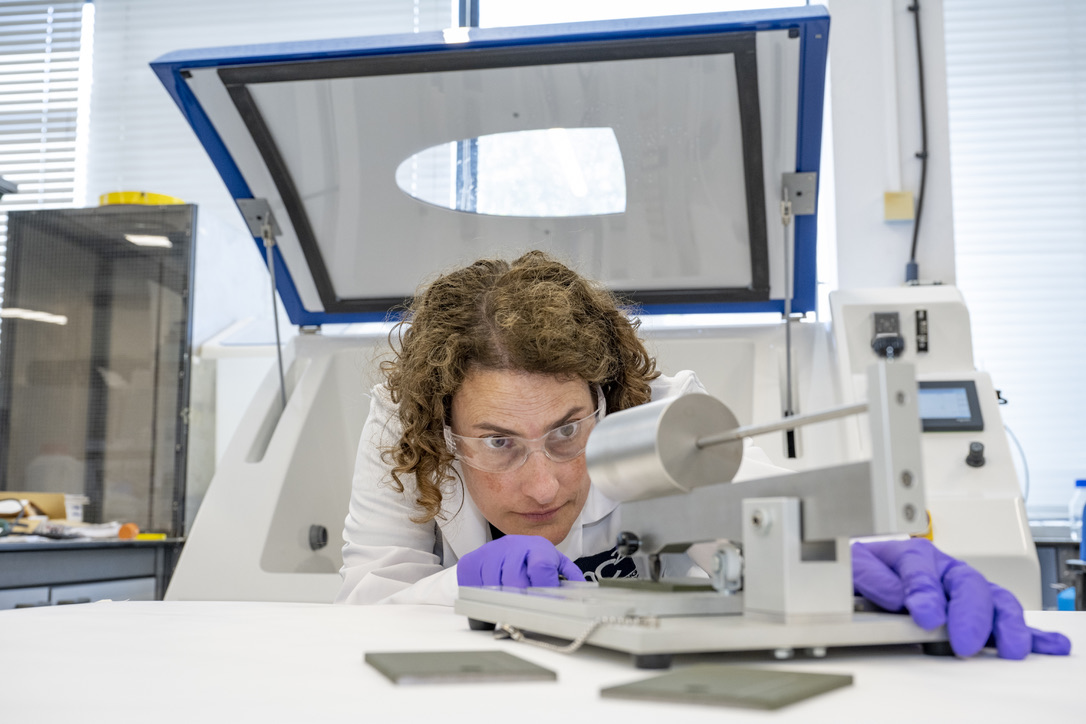

I work on a range of projects, but mostly in the areas of corrosion control and paint and coatings testing, working with Spencer Court.

I have a particular interest in advising on suitable accelerated corrosion test packages, including providing bespoke test regimes where required.

Rachel Triggs

The purpose of this is to determine how well paints, coatings or materials are likely to perform in their in-service environment. We use a range of equipment to look at how samples corrode or degrade under conditions such as salt spray, humidity, UV and immersion in water.

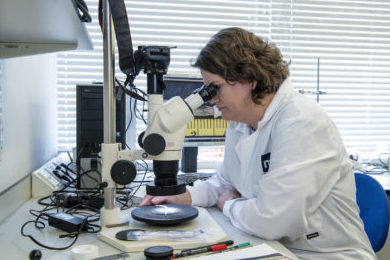

Sometimes I also support Nicola Symonds’ failure investigation work, for example by carrying out imaging and microscopy.

It’s a really diverse job with plenty of variety – even if you’re using the same equipment day to day, the materials and the reason for the testing are different for every project.

What did you do before joining the nC2 team?

From 2000 to 2015 I was an Aircraft Corrosion Control and Husbandry Higher Scientific Officer at the Ministry of Defence (MOD). This involved providing scientific and technical advice to the users and maintainers of military aircraft to preserve the material condition of the aircraft.

The work was very varied, and ranged from rapid advice to the front line on urgent matters regarding aircraft materials, to long-term projects coordinating research into corrosion control methods.

A favourite project of mine was investigating the effect of plastic media paint removal on aircraft structures. This technique is significantly more environmentally and health and safety friendly than traditional chemical methods but there were concerns over the effect on aluminium-clad surfaces and thin-skinned structures. My role involved understanding and defining the requirement for testing, devising suitable scientifically rigorous test procedures, coordinating aspects of the project and writing the final report.

As a result of the work, plastic media stripping was safely introduced into the MOD, enabling the MOD to reduce its environmental impact and improve working conditions for the painters.

Paint testing

What did you bring from this role to your work at nC2?

While at the MOD I developed skills in project management, time management, communication with customers and seeing the bigger picture, as well as technical skills.

What do you enjoy about your current role?

There is huge variety in the types of jobs that come in and it is never routine. I particularly enjoy taking a customer’s requirement and turning it into a package of work that will give them the answers they need. More often than not, bespoke tests or analysis techniques need to be created for the customer. Adapting standards and specifications for the task in hand and then communicating these with the customer is a particular highlight for me.

I also enjoy writing a report clearly and concisely to ensure that the customer has all the information they need.

What are you working on at the moment?

I’m currently working on a project for HMS Victory. The hull planking needs to be replaced and so we’re working in partnership with the conservation team at the National Museum of the Royal Navy to ensure that the most appropriate paint and sealing materials are selected to ensure that the material integrity of the ship is maintained.

This has involved identifying and implementing the most suitable tests to scientifically assess the candidate materials’ suitability for use in such a unique environment.

Rachel on a site visit to HMS Victory

For example, we’re doing immersion tests to find out how well the paints withstand water passing through into the wood underneath, and humidity and intermittent salt spray tests to determine how well the metal fixings within the planking will cope with the HMS Victory environment.

Having worked for the MOD on modern military vehicles, helping to preserve part of our military heritage is a lovely connection. Knowing that we’re helping to maintain a real national treasure for future generations to see and experience is very rewarding.

What made you want to go into an engineering/scientific career?

I knew at primary school that I wanted to be a scientist. I was fascinated by the world around me and would often experiment with everyday household products like shampoo and vinegar to see what would happen if I mixed them! The deeper I got into science, the more I loved it. When I was coming towards the end of my chemistry degree I was keen to get out of academia and start solving some real-world problems.

What is it like to be part of the nC2 team?

nC2 is a fantastic place to work. It is a diverse, compact team with a wide range of skills and experiences. Everybody helps each other out and the communication between team members is excellent. I have been welcomed into the team by everyone and my thoughts and opinions have been listened to. It’s clear that everybody enjoys their work and is focused on doing the best possible job for our clients.

What do you see as nC2’s strengths?

It has strengths in lots of areas:

- Communication – nC2 takes the time to really listen to, and understand, a customer’s requirement, and to keep the customer updated on task developments. Our outputs are detailed and clear.

- Expertise – the staff at nC2 really know their stuff! It is so much more than a test house. Where very specialist expertise is required, we have access to academics within the university.

- Flexibility – nC2 can change the direction of a project where required. We are not limited by the requirement to use off-the-shelf test methods but can adapt and change programmes of work to meet client’s requirements.

- Cost – our services are not overpriced and we’re not only interested in profit.

What would you say to a company that was considering using nC2’s services?

Go for it! nC2 provides a bridge between industry and academia and you will be hard placed to find another organisation that can combine the expertise and flexibility of nC2. We will partner with you to ensure that you are getting exactly what you need from us at every stage of the work programme.