Understanding a material’s composition, how it is affected by in-service conditions or why it has gone wrong can be essential for product development and to remedy problems.

Metallurgical analysis is a destructive technique that we can use to examine your material. Traditionally used to examine metals, it can also be applied to other materials such as coatings, plastics and composites.

We often use it in combination with mechanical testing or chemical characterisation to provide a comprehensive picture for our clients.

For example, metallurgical analysis can help us determine:

- the elemental composition of your material and whether it meets the desired specifications for use

- the grain structure of the material (with etching and EBSD)

- characteristics such as conductivity, hardness or porosity

- the effect of processes performed on your material, such as temperature

- the characteristics of different layers of a composite using cross-sectioned samples

- evidence of degradation or corrosion.

Metallurgical analysis team

We are experienced in using these techniques across a wide range of industry projects. Examples include examining each layer of a composite used in tubing to measure porosity and identify damage, measuring copper wire before and after environmental testing to check for changes in diameter, and identifying microstructural changes in a metal to understand the progress of an aircraft fire.

Metallographic preparation of samples

Our metallurgical analysis service

Having selected the optimal techniques to meet your requirements, we will prepare and examine your material. We have an array of specialist facilities including high-precision equipment for imaging and measurement. Services include:

- photography

- sample preparation including polishing and chemical etching

- optical and scanning electron microscopy (SEM)

- positive material identification using energy dispersive X-ray spectroscopy (SEM/EDX) or optical emission spectroscopy (OES)

- micro and nano hardness profiling

- Vickers hardness

- conductivity of aluminium

These techniques can be carried out in conjunction with surface metrology, mechanical testing and chemical analysis.

Once we have completed our analysis you’ll receive a full report including metrics and expert interpretation. We’ll also be happy to discuss the findings with you.

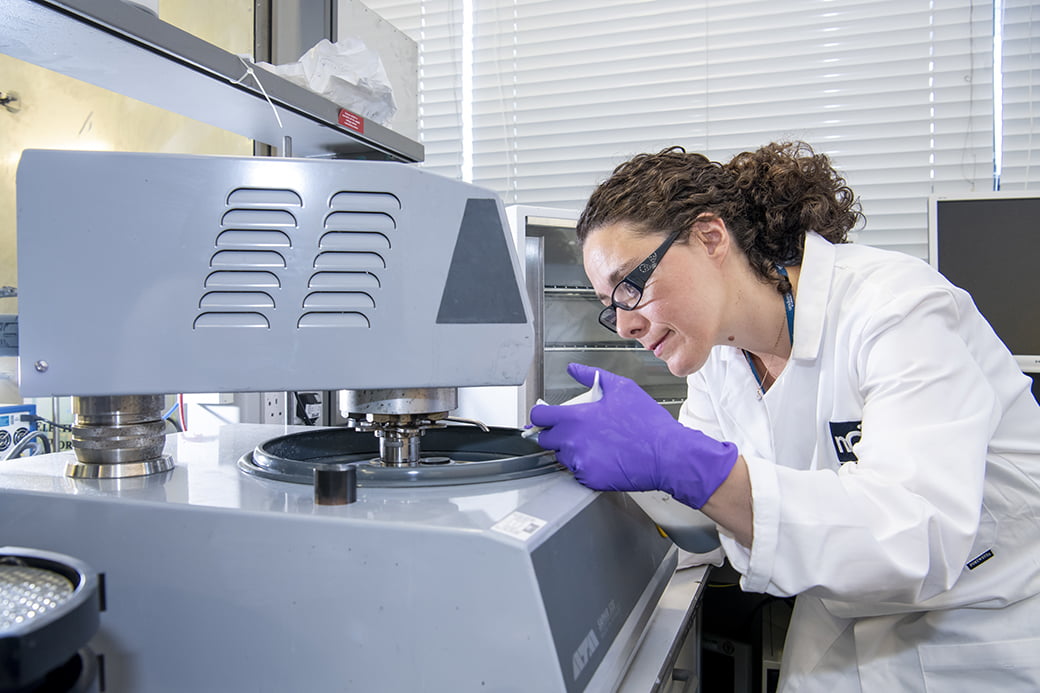

Meet our metallurgical analysis expert

Dr Ilaria Corni leads on our metallurgical analysis projects. A specialist in materials characterisation, she has in-depth knowledge of nC2’s suite of equipment and is highly skilled in metallurgical techniques, including sample preparation and imaging. She has a wealth of experience in the application of these techniques to industry projects. Find out more about Ilaria.

Dr Ilaria Corni

What we offer

- Free initial consultation and bespoke quote, which may include free practice tests to determine the best test plan – if you’re not sure exactly what you need, we can advise you.

- A choice of packages to suit your requirements.

- Tests tailored to your needs, run by specialist staff in our state-of-the-art labs.

- A comprehensive report including results and expert advice, plus a meeting to discuss the results.

Why choose nC2?

- A testing and analysis service of the highest quality.

- Access to specialised facilities and knowledge across the University of Southampton.

- Packages to suit your budget and requirements – whether you’re looking for a one-off test or support for a major project.

- Excellent customer service – we’ll keep you in the loop every step of the way.

- High levels of customer satisfaction.