Dr Ilaria Corni, Head of Operations and Principal Consultant, heads up nC2’s industrial research and also uses her expertise in materials characterisation and electrochemical deposition in the labs. A talented project manager, she has oversight of all nC2’s activities as well as managing the consultancy’s marketing and finances.

Ilaria joined us in 2016 having worked as a researcher at the University of Southampton since 2009. She has a master’s degree in chemistry from the University of Modena and Reggio Emilia in Italy, a PhD in materials science from Imperial College London, and is a Member of the Institute of Materials, Minerals and Mining (IOM3).

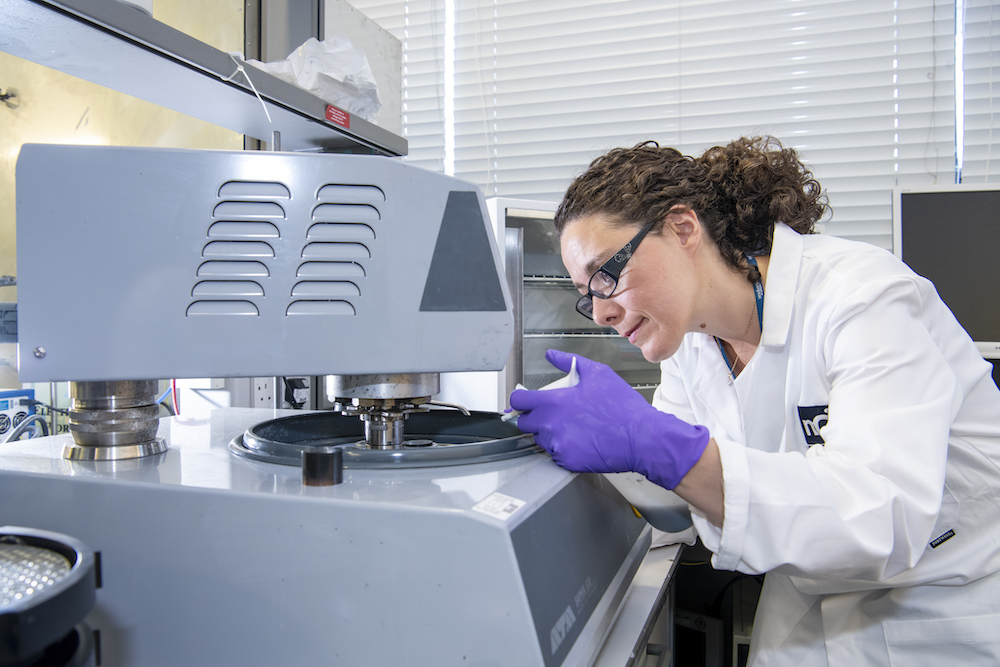

Dr Ilaria Corni

Tell us more about your role at nC2

I’m the lead for nC2’s industrial research projects – I do all the technical and project management work for them. That’s one of our services – helping companies to find partners and apply for government funding for research projects. I also do literature reviews, to help clients understand the state of the art in the particular area they are working in, and what their best next steps might be.

In addition, I do metallurgical and materials characterisation work for other nC2 projects, such as failure investigations. This includes preparing samples, taking images and writing up information for reports. We have excellent facilities for materials characterisation; we can do scanning electron microscopy, energy-dispersive X-ray to understand the composition of a sample and X-ray diffraction to look at its crystalline structures. I am also the first point of contact and project manage most of the jobs that are done in collaboration with experts that are not part of nC2.

As Head of Operations, I also look after nC2’s finances and marketing, manage our projects and help with business planning.

I enjoy having lots of different hats – it’s really varied and I like having an overview of everything that’s going on. It’s also extremely satisfying knowing that the results make a difference and help our clients to make decisions and move ahead with their research, planning and design.

Why is the project management side of your role so crucial?

I know how important it is for the client to have the answers to the questions they ask us, so it’s essential to do things to deadline and complete our projects as efficiently as possible. Good project management is key to doing that, and I enjoy that side of things very much.

nC2 Leadership Team

Preparing cross-sections for inspection

What originally made you want to go into an engineering/scientific career?

I loved scientific subjects at school, mainly maths, biology and chemistry. I liked them because they have a right or wrong answer – I enjoy things that are black and white.

Tell us about your early research career

My PhD focused on the deposition of coatings using electrochemical techniques, which is useful in my work at nC2. As part of this research I wrote a literature review, entitled Electrophoretic deposition: From traditional ceramics to nanotechnology, that has been cited more than 500 times.

Following my PhD I joined the University of Southampton as a research fellow at the national Centre for Advanced Tribology at Southampton (nCATS). I worked on research into impact and erosive resistance of coatings for body armour, and did some consultancy work for external clients.

After four years I was seconded to Perpetuum Ltd, a University spin-out company that was developing self-powered vibration sensors to monitor the condition of train bearings. It is a fantastic system that helps train companies maintain their stock to avoid serious problems, or if necessary take a train out of service to avoid a catastrophic failure. My work focused on forensic engineering of rail bearing failures and analysis of vibration, and during this time I published several papers and presented at conferences.

How has this experience fed into your research role at nC2?

At nC2 I have continued to work on rail fatigue monitoring, heading up two industry research projects funded by Innovate UK.

One was MONAXLE, a project to develop sensors to detect cracks in train axles, which we worked on in collaboration with Perpetuum Ltd, TWI and the University’s Electronics and Computer Science department. We designed and built a bespoke rig to test this novel technology, testing scaled axles under four-point rotating bend conditions. This project is now complete.

For BEARING EYE, we are helping to develop a new instrument to map and interpret the surface damage observed in failing rail axle bearings, working with Perpetuum Ltd and Scantron Industrial Products Ltd.

What’s your approach to working with clients?

The clients are our focus. We always do our best to get results to them in the quickest time possible, but we also like to create a relationship with them. We have lots of repeat clients – that’s the best endorsement and it’s so motivational as well.

We’re very flexible in the way we work with clients and offer different ways for them to engage with us. We provide a free quote, and if they want to go ahead we will write a contract which might include different work packages, so the work can be done in stages. If halfway through a project we find something that makes us think we should change direction, we’ll advise the client and agree a new way forward rather than sticking to the original proposal.

Working on an industry research test rig

What do you think sets nC2 apart from other engineering testing services?

We’ve got equipment that most test houses can’t even dream of. If specialist equipment is needed for a job, we can search within the University to find the right instrument – and an expert to help us use it. We can tailor the team too, depending on the expertise needed for a job, by bringing in specialist academics from the University.

We can also introduce clients to other companies that could help them to progress an idea and help them apply for research funding to implement it.

We pay a lot of attention to detail in every project. We don’t only do testing, we will also analyse the sample, for example to measure the depth of a crack or crater, and cut through it to see what kind of mechanism created the damage. It’s a full package, not just a one-off test.

What do you enjoy about being part of the nC2 team?

I love working at nC2 and I’m proud to be part of it. We are a good team and we collaborate really well. I work with different team members depending on the type of project, and sometimes everyone gets pulled into large jobs. It means you pick up new learning from colleagues, as well as getting to know them better.

Also the work is very flexible. I work part time and because I have two school-aged children I have been mostly working school hours – but at the same time I don’t want to let clients down and I always put in extra hours when I know that a job needs to be finished. When you are proud to be part of a team you do it because it needs to be done.