Using surface metrology we can measure the roughness, texture, shape and form of a sample’s surface.

We typically use this technique to provide extra information for friction, wear and erosion testing projects, and to help identify failure mechanisms. For example, surface metrology enables us to:

- measure the roughness of a surface before and after testing

- accurately measure volume loss after a wear test, or

- confirm whether our lab-simulated wear matches in-service wear

- map rough textures such as fracture surfaces to help determine why a component has failed.

From using a portable profilometer to measure the surface of railway tracks in situ, to nanoscale characterisation with atomic force microscopy of thin films for novel electronics devices, it’s a technique we use across many types of test and investigation.

Our surface metrology service

With both contact and non-contact systems at our fingertips we can offer flexible solutions. We will select the most appropriate metrology tools depending on the size and location of your sample material and the type of data required.

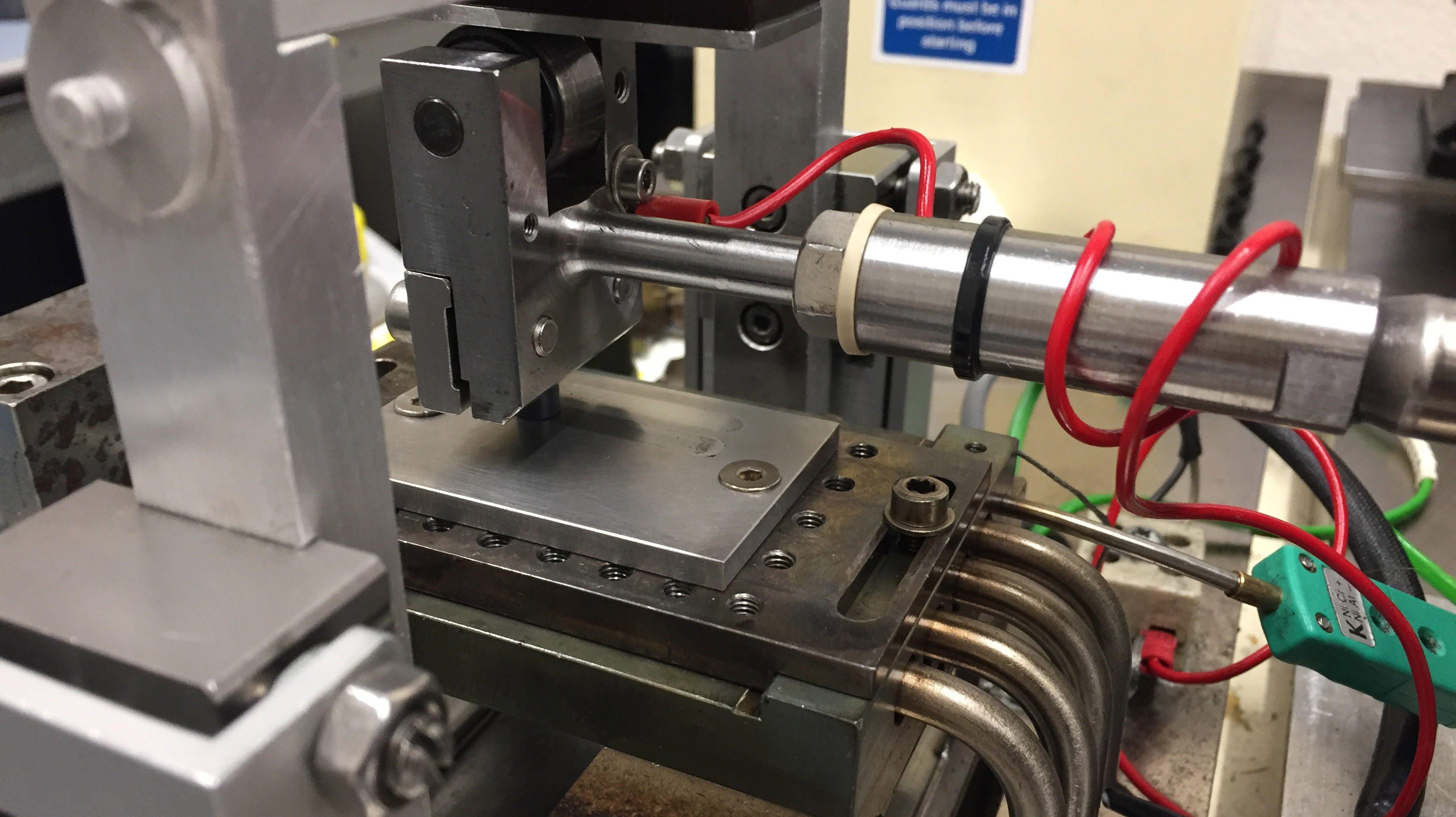

- Contact systems include a hand-held Surtronic S125 and a semi-portable Form Talysurf Intra Touch.

- We have two non-contact (optical) systems for high-precision 3D surface mapping: the PROSCAN 2100 profilometer and the Alicona InfiniteFocus 3D mapping system.

- Where it is not practical to test a surface in situ, we can use a quick-setting compound to replicate a surface to 0.1 of a micron, and take the replica to the lab for testing.

- Specialist instruments for thin film characterisation, including Kelvin probe and atomic force microscopy (AFM).

Data analysis

We will analyse the data, usually in the context of a suite of test results and measurements. Our expert team will provide a full report and will be happy to discuss the findings with you.

2D surface profilometry using the Intra Touch

Meet our surface metrology experts

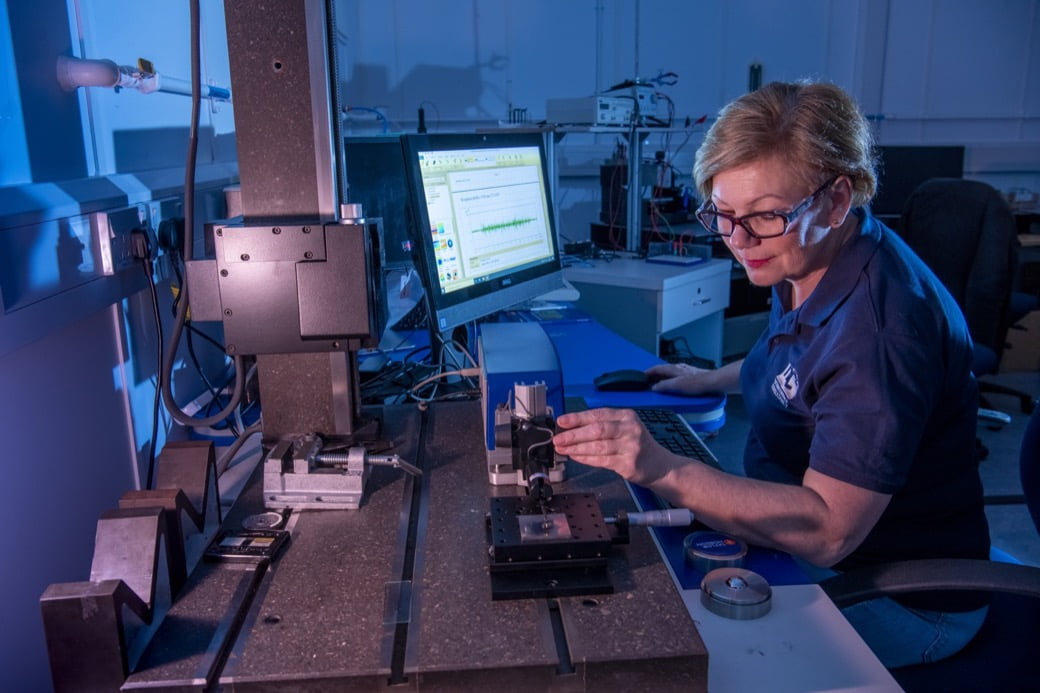

Professor Nicola Symonds, Director of nC2, has extensive experience of using surface metrology as part of failure investigations and projects involving friction and wear testing. She will work with you to understand your requirements, apply the optimal metrology techniques and provide in-depth analysis of the results, ensuring you gain the insights you are looking for. Find out more about Nicola.

Professor Nicola Symonds

Dr Dimitra Georgiadou specialises in the fabrication and characterisation of thin film and optoelectronic materials and devices. With more than 15 years’ experience in this field, including collaborations with industry, she is skilled in the use of advanced techniques, such as Kelvin probe and atomic force microscopy (AFM). We call on Dimitra’s expertise when clients come to us seeking insights into novel thin films, including flexible and opto/electronic materials. Find out more about Dimitra.

Dr Dimitra Georgiadou

What we offer

- Free initial consultation and bespoke quote, which may include free practice tests to determine the best test plan – if you’re not sure exactly what you need, we can advise you.

- A choice of packages to suit your requirements.

- Tests tailored to your needs, run by specialist staff in our state-of-the-art labs.

- A comprehensive report including results and expert advice, plus a meeting to discuss the results.

Why choose nC2?

- A testing and analysis service of the highest quality.

- Access to specialised facilities and knowledge across the University of Southampton.

- Packages to suit your budget and requirements – whether you’re looking for a one-off test or support for a major project.

- Excellent customer service – we’ll keep you in the loop every step of the way.

- High levels of customer satisfaction.