Sam Hambrook, Senior EngineeringTechnician, joined nC2 in 2019 and has rapidly become an invaluable part of the team, skilfully supporting her colleagues’ testing work.

Having been a police officer, yacht skipper and small business owner, she’s well equipped to deal with the demands of this busy and varied role.

Sam is a Technician Member of the Institute of Materials, Minerals and Mining.

Sam Hambrook

What does your job involve?

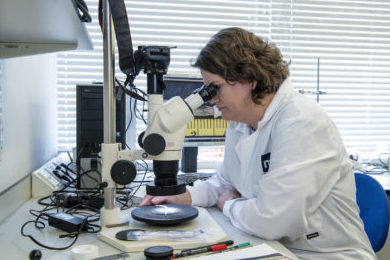

I support the whole team on their projects. That includes photographing samples at various stages of the testing process, and preparing samples for tests. I also use the microscopy camera to produce images which are used for taking measurements.

I help to run tests too, for example working with JB on the slurry erosion rig and using the TE77 tribometer, which measures sliding wear and friction. During the COVID-19 lockdown I had the Taber Abraser wear testing machine in my house and prepared a user guide for it, so I’m becoming an expert in that!

It’s a really diverse job with plenty of variety – even if you’re using the same equipment day to day, the materials and the reason for the testing are different for every project.

Tell us about your roles before nC2

When I left school I joined the Metropolitan Police, and was there for 10 years. After that I did some dinghy sailing, taught sailing for a while, retrained as a yacht skipper and did some big yacht racing and moved yachts around the world. Then I got pregnant, came back to the UK, and had to get to grips with having two disabled children. I wanted a job that would fit around with my caring role, and at the time my eldest son was having massage and aromatherapy. This gave me the idea to set up a massage business with staff going into offices and working with private clients offering sports massage. When the opportunity arose at nC2 I was thinking I wanted to do something else and it turned out to be the right thing.

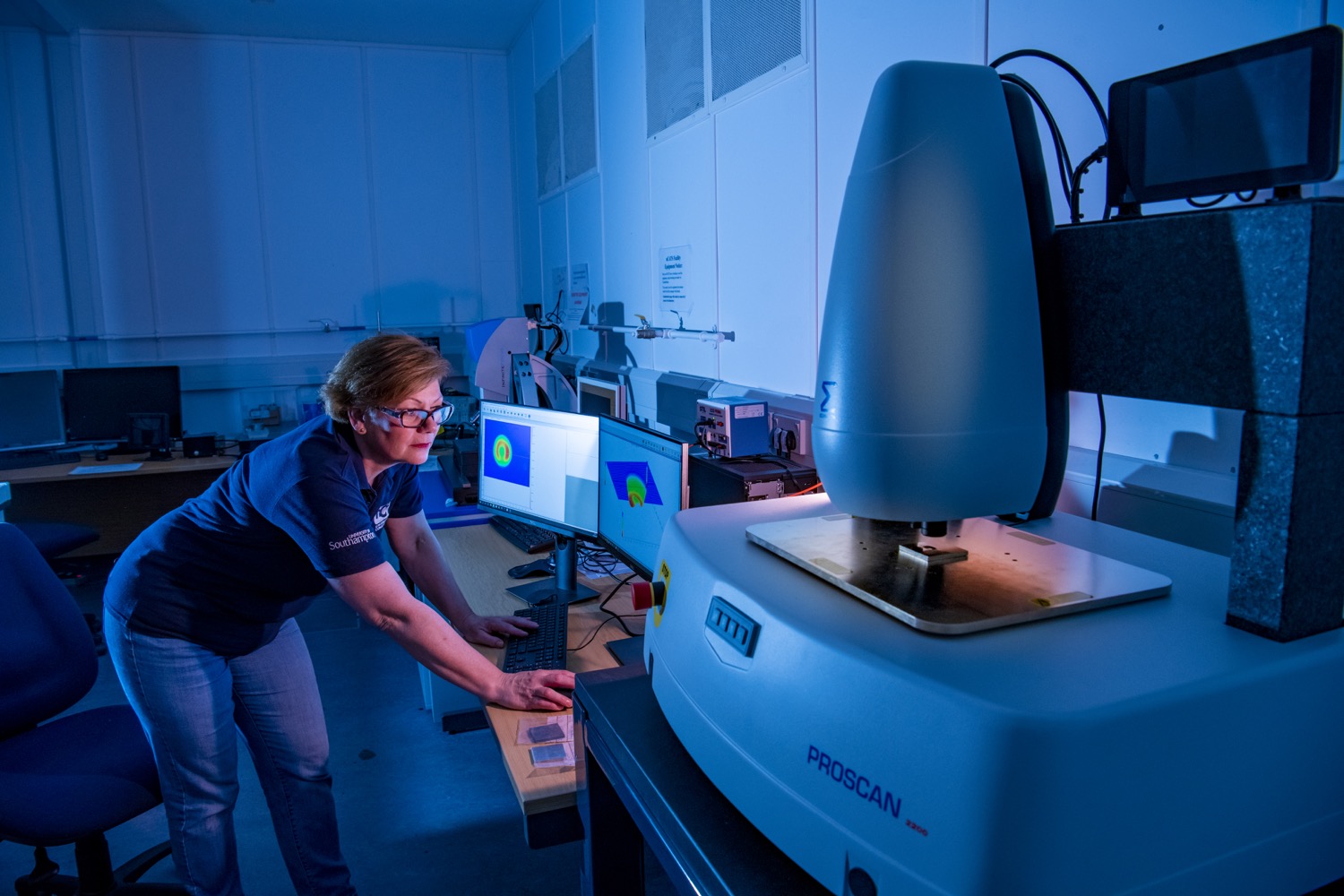

Detmining the profile of a damaged surface

Why did joining an engineering consultancy appeal to you?

I’ve always had an interest in science but was pushed towards arts and humanities at school. I couldn’t work when my children were younger, so I decided to study with the Open University, doing science, molecular physics and maths modules. I enjoy studying science because I like taking things apart and finding how they work (or don’t work), which is quite helpful in terms of this job.

How are the skills you developed in previous roles proving useful at nC2?

Because I’ve had lots of different experiences work-wise, I can deal with different tasks and demands. That’s what I like about this job, there’s always something different coming in and there’s always some problem solving to be done – in engineering you’re creating solutions at all levels.

I’m used to managing myself and my own time – though sometimes everyone wants me at the same time to do things!

My policing experience comes in handy for doing ‘as received’ photography at the start of a project, which means recording samples as they come in and are unpacked. It’s my job to take images and get everything labelled and bagged up – it’s a bit like being an evidence officer.

What sort of projects are you working on?

I’m working on the HMS Victory project, where we are supporting the ship’s conservation team by helping them to choose the most suitable caulking, glue and paints to make the ship watertight.

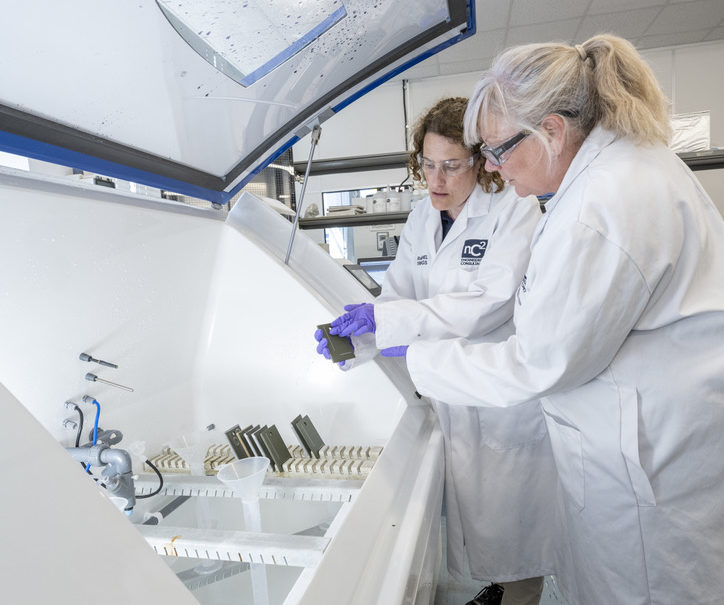

For the glue and caulking this involves shear and tensile tests – which involves taking bonded samples and pulling them apart to simulate real-life loading. The tests are done at different temperatures, and after the samples have been immersed in water, so it’s quite a complex set of tasks. Other tests we are conducting are cross-cut, where we score the paint and pull off tests using adhered dollies. I’m also using microscopes to measure the thickness of the paints applied to the wood.

Site visit to HMS Victory

We went to visit the ship which was great as we could see what our work was contributing to. There’s a sense of satisfaction from doing something for such a historical ship.

I’ve worked with Ilaria on the MONAXLE project, which is looking to improve safety on the railways through the detection of cracks in train axles. I’ve helped with testing on the rig, which runs a scaled axle with bearings to measure sound and vibration, heat and speed.

Environmental testing

What part of the job do you find most satisfying?

Failure work piques the investigator in me. And for accident investigation work you know you’re part of something bigger – it really is a matter of life and death and we may be able to say “fix this and it won’t happen again”. It’s good to be able to play even a small role in that.

What do you enjoy about being part of the nC2 team?

Everyone in the team is an expert but they’re all prepared to listen to me if I’ve got suggestions and ideas – it’s really good to be able to have an input and for it to be valued. The team works well socially and I’m able to juggle my working and caring roles easily and know that the others are supportive and flexible.

What do you see as the consultancy’s main selling points?

We’re part of the University so although we’re a small unit we have access to a large resource in terms of equipment and knowledge. All the staff are experts in their field and there’s a pride in the standard of work – whatever the job is, we’ll get it done properly.