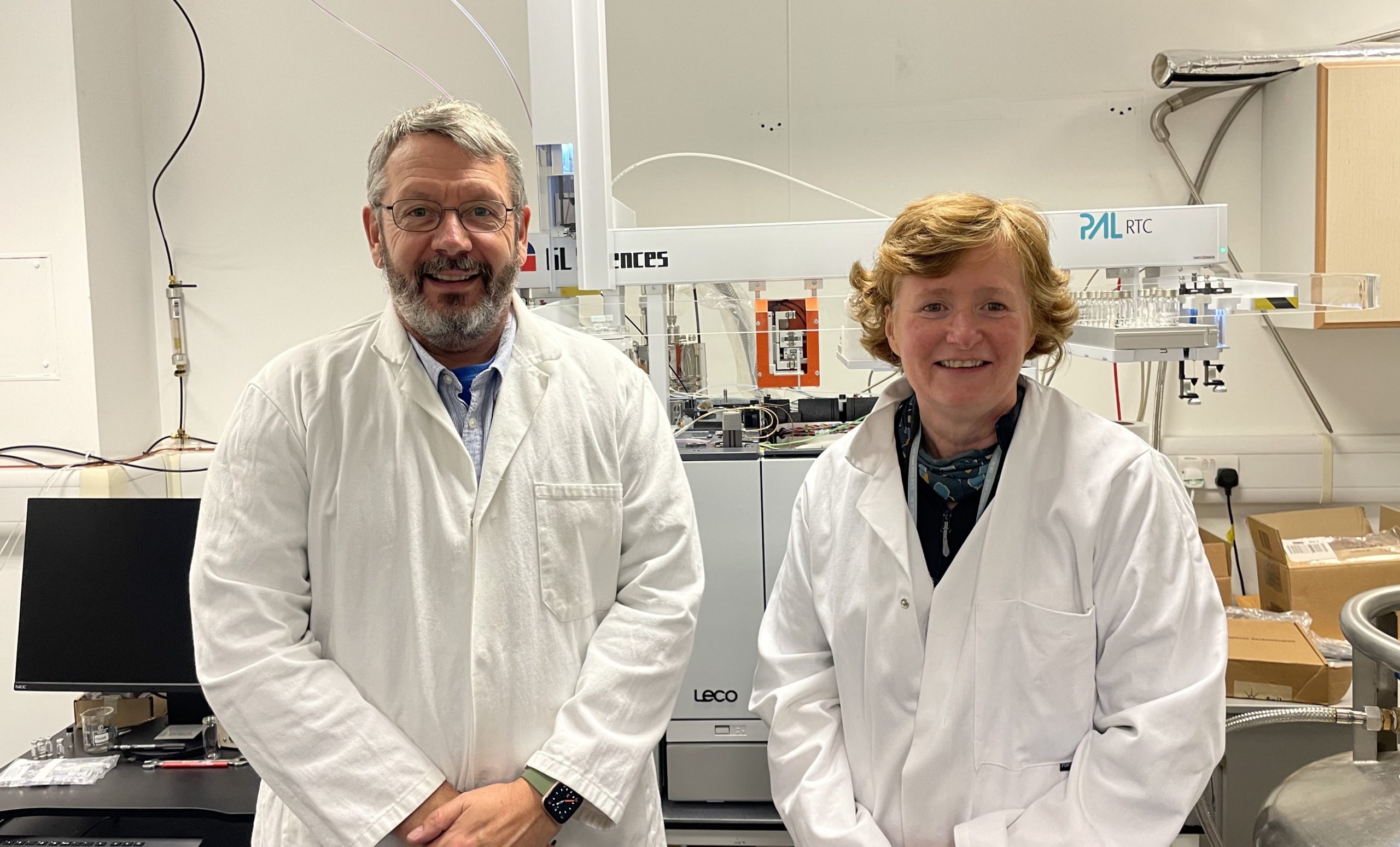

Throughout March we’re celebrating nC²’s brilliant women engineers, inspired by International Women’s Day 2024. This week, meet Professor Nicola Symonds.

Role: Director

Area of expertise: Failure/accident investigation

Career in a nutshell: Led nC² since its establishment in 2015, after 10 years working on accident investigations in the Ministry of Defence

Best thing about the job: “Leading, working, and having fun with such an excellent and diverse team.”

Most proud of: “Providing my expertise to support the five-year Air Accidents Investigation Branch investigation into the 2018 Leicester City Stadium AW169 helicopter crash, which was published in 2023.”