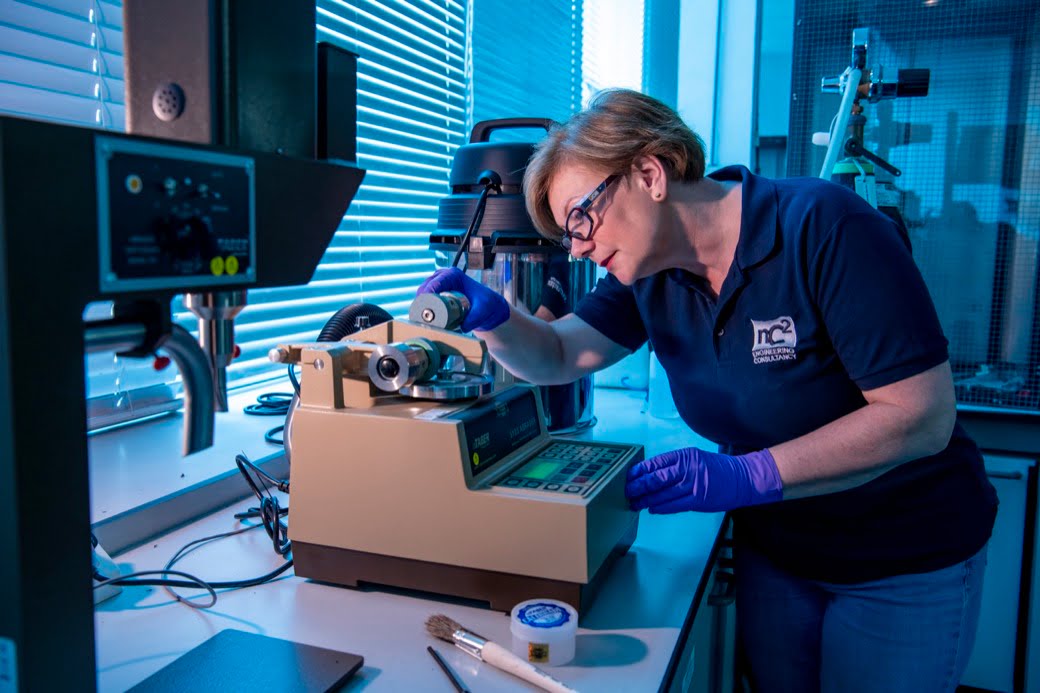

We’d like to introduce the Engineering Design Manufacturing Centre here at the University of Southampton. Their expertise and state-of-the-art equipment ensure that our clients receive a top-notch service at every stage of their projects. Watch the video for highlights.

Whether it’s handling delicate samples with utmost precision or crafting bespoke parts to exact specifications, our technicians go above and beyond to deliver excellence. We take pride in our commitment to understanding and meeting our clients’ unique project and sample requirements, providing not just services, but true partnerships in success.